Home \ International \ Berco launches Platinum Line products offering increased undercarriage lifetime and reduced cost per hour

Berco launches Platinum Line products offering increased undercarriage lifetime and reduced cost per hour

19/03/2019

Pubblicato da Redazione

Berco launchs its Platinum Line of products for the aftermarket at Bauma 2019

Berco is pleased to announce the launch of its Platinum Line of products for the aftermarket at Bauma 2019. The Platinum Line consists of products focused on improving undercarriage lifetime and reducing the cost per hour of operation for the mining, large construction and oil and gas markets.

“Our Platinum Line consists of products that are the state of art technology in the market. The idea is to position Berco as the ‘top of mind’ product provider for the global market for large machinery,” says Piero Bruno, Berco CEO.

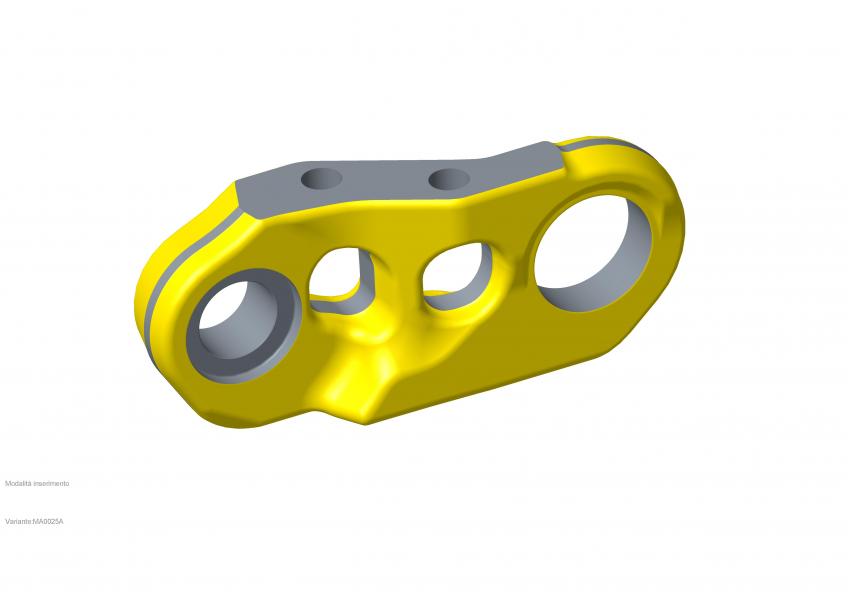

Reliability is key for Apron Feeders used in sand treatment in the oil and gas markets, since a feeder failure means the loss of millions of dollars for each day of stopped work. Low temperature and high load spectrum common on these applications are a huge challenge for a system designer. To improve feeder reliability, Berco developed a unique high strength track link. Made of a new material, via a newly-dedicated manufacturing and treatment process, this link offers double the fatigue life compared to similar products on the market. Berco's high strength track links also reduce the need for maintenance stops.

As an example of Berco engineering’s knowledge, the company has developed a solution for bucket wheel excavator teeth. Using its forging technology, and material and heat treatment expertise, Berco created a more resistant, light weight and higher performance Ground Engaging Tool. By using high quality steel and advanced mechanical superficial heat treatment, Berco provides an extended life of this product. Additionally, Berco designed a solution for faster connection to the bucket to reduce needed replacement work in the field. As the wear of forged bucket teeth can precisely be predicted (compared to casted solutions), preventive maintenance can be much more efficient and accurate.

“Berco Platinum Line products are aimed at customers who are looking for high quality solutions that can provide a great value/benefit ratio to their business,” says Bruno.

For the large mining dozer market, Berco is releasing the 800 HP track chain, a tailor-made solution for heavy duty application. This new product is applicable in all weather conditions, extends wet joint life up to 30%, and reduces maintenance stops. The Berco 800 HP track chain is designed with a reinforced link and uses bigger pins and bushings with a compatible sprocket and a higher link, offering major resistance to the large amount of load on the undercarriage. This chain also uses a new generation seal and incorporates our BPR2 solution.

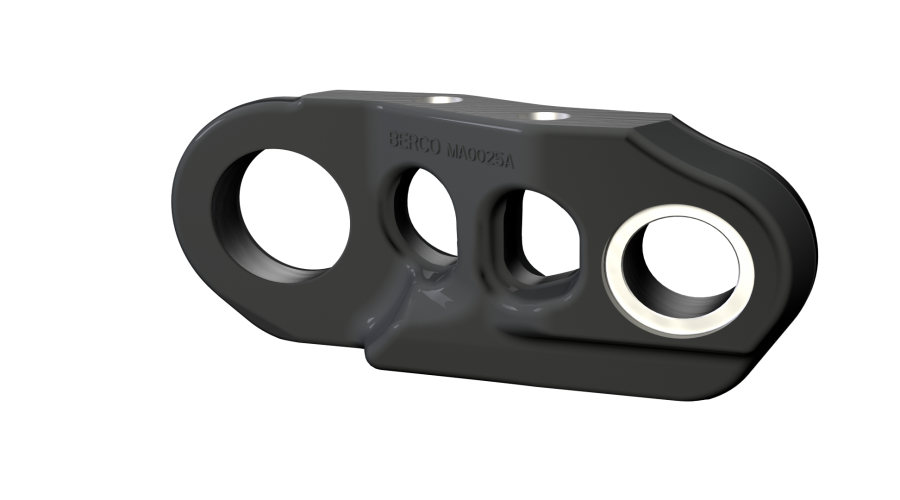

Berco launched Robustus

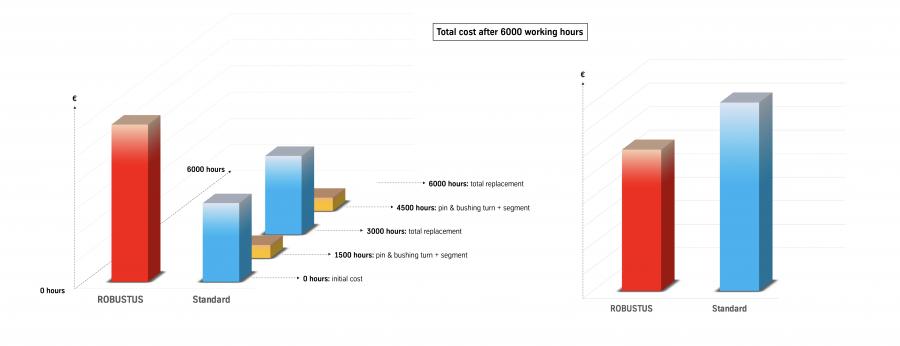

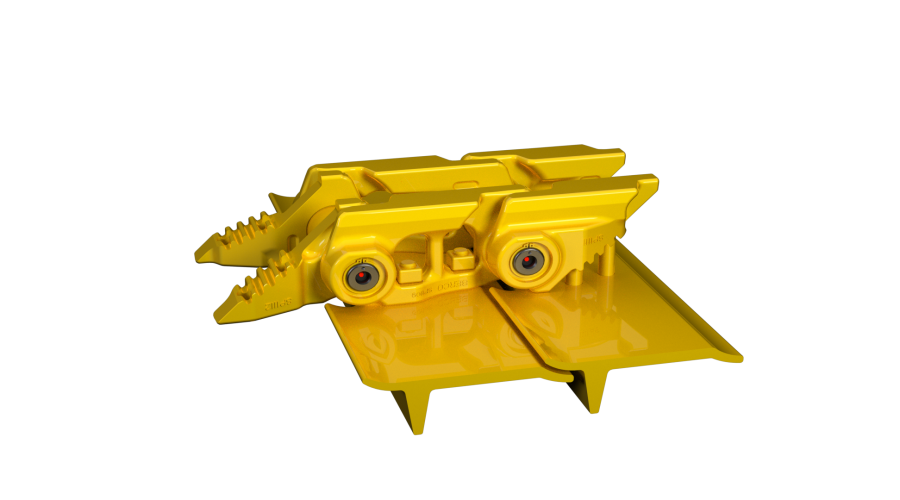

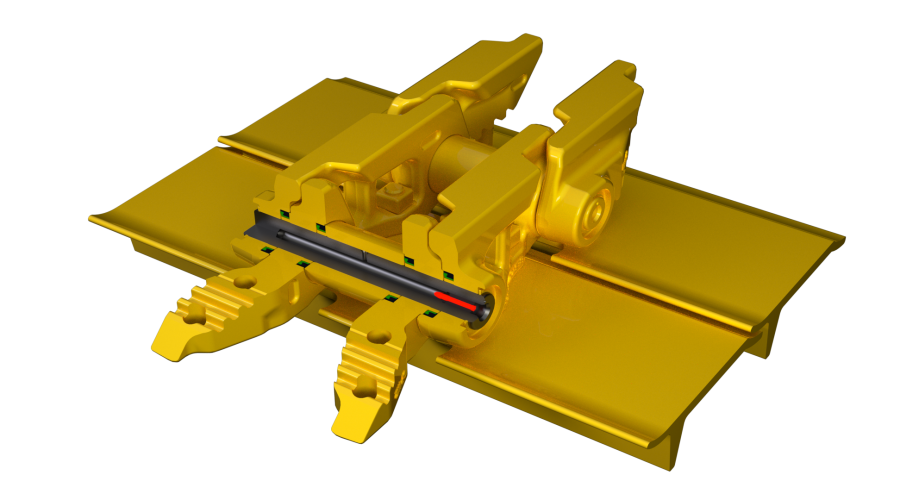

Aimed at the construction dozer market, Berco launched Robustus, a new – patented - technology track chain that increases undercarriage lifetime by 35%, offering up to 6,000 maintenance-free hours and reducing cost by 25% compared to other track chains on the market. Robustus allows the bushing to rotate separately from the linkage system, dramatically decreasing wear on both the bushing and sprocket. With reduced friction between the sprocket and bushing, wear life is extended, and higher durability and lower operating costs are realized.

About thyssenkrupp Forged Technologies

The Forged Technologies business unit is part of the thyssenkrupp Group's component business area, which generated sales of 7.9 billion euros with around 35,000 employees worldwide in the last fiscal year. Forged Technologies' product portfolio includes forged and machined engines, transmission and suspension components, such as crankshafts, rotor shafts and connecting rods, as well as undercarriage systems and components like track chains, rollers, carrier rollers, idlers, drive sprockets and track shoes. This machinery and undercarriage equipment are mainly used in the raw materials, construction and agricultural sectors. In the course of the planned separation of the thyssenkrupp Group, Forged Technologies will, in the future, be part of the thyssenkrupp Materials division, which combines steel and stainless steel production, materials trading and steel-related processing.

Ultime notizie di OnSite News

Earthmoving Machinery

25/11/2024

Prinoth Unveils Expanded Production Facility in Granby, Canada

Prinoth held an event to announce the official opening of it...

Logistics

22/11/2024

Sarens acquires additional SCHEUERLE SPMT K24 modules

renowned for its expertise in crane rental services, heavy l...

Equipments

21/11/2024

SITECH partners with Royal Engineers to create poppy and demonstrate tech offering

The demostration involved creating a ground-level poppy desi...

Earthmoving Machinery

20/11/2024

Strong and stable RA30 trucks carry the weight at New Caledonian mine

Three Rokbak RA30 trucks are delivering exceptional durabili...

Lifting

20/11/2024

Tadano AC 7.450-1 Performs Double Duty in Wisconsin

A cost-saving and versatile solution was already on site - a...

Lifting

11/11/2024

Tadano AC 7.450-1 all terrain crane for the Victoria Tower in Mannheim

Tadano AC 7.450-1 all terrain crane lifts cooling unit to to...

Altri International

International

25/11/2024

New Grove GMK3060L-1 drives busy schedule for Mann Crane Hire

• Mann Crane Hire selected the GMK3060L-1 for its class-lead...

International

25/11/2024

Prinoth Unveils Expanded Production Facility in Granby, Canada

Prinoth held an event to announce the official opening of it...

International

23/11/2024

GPMat International takes delivery of two Raimondi T147s residential development in the South of France

- Official agent of France expands its product lineup with t...

International

22/11/2024

Sarens acquires additional SCHEUERLE SPMT K24 modules

renowned for its expertise in crane rental services, heavy l...

International

22/11/2024

Five WOLFF cranes modernize Oslo’s Ulven district

With a total of five WOLFF cranes of type 7534.16 Clear, Wol...

International

21/11/2024

Kleemann: New compact crusher used for recycling

Impact crusher MOBIREX MR 100i NEO impresses during operatio...