Home \ International \ Dynapac MF2500CS – IMIX: Engineered to amaze!

Dynapac MF2500CS – IMIX: Engineered to amaze!

27/12/2022

Pubblicato da Ettore Zanatta

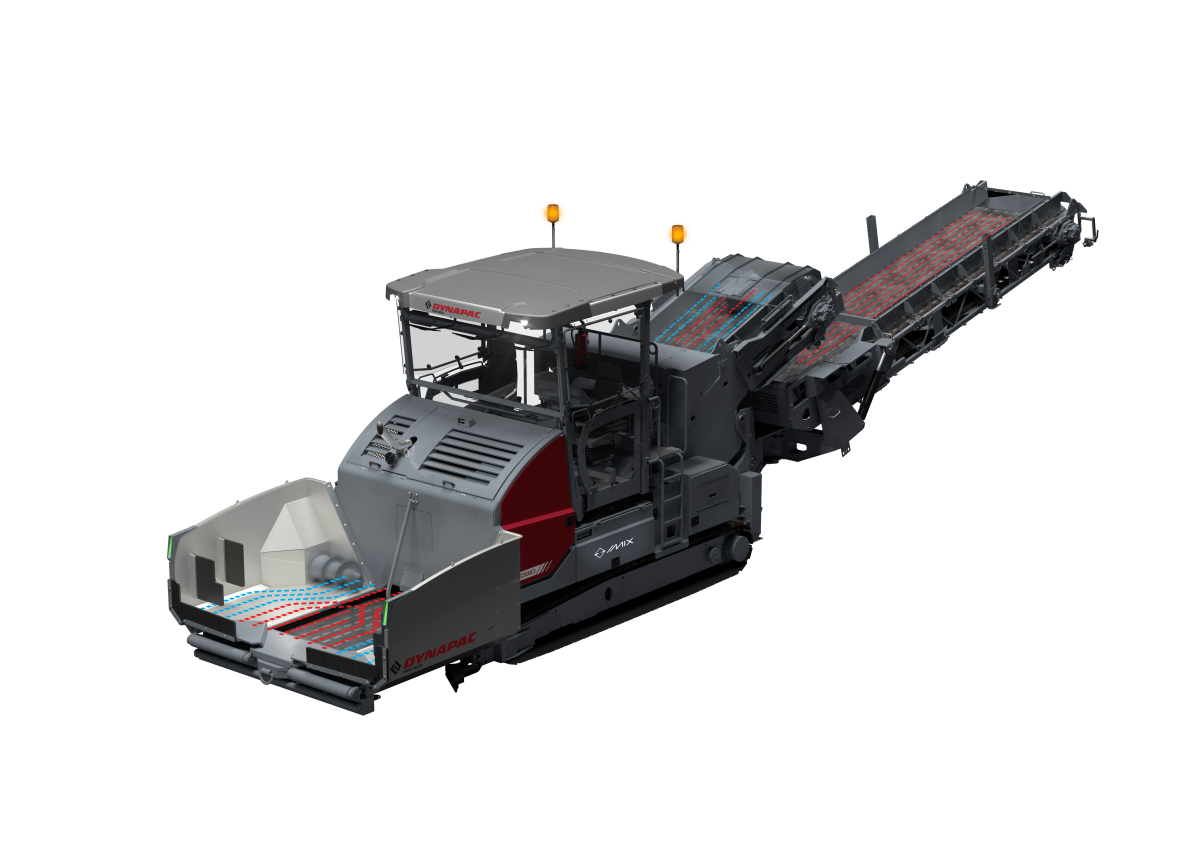

The Dynapac MF2500 IMIX is the ideal choice for more lasting performance, operating ease and cost-saving, C02-reducing features.

Roads are built with quality and longevity in mind: that’s why the Dynapac MF2500 IMIX is the ideal choice for more lasting performance, operating ease and cost-saving, C02-reducing features. At the heart of the IMIX-system is the combination of three smartly positioned devices: a conical auger in the hopper, a flow divider in the conveyor and a mixing system at the end of the main conveyor. Together, they equalize the temperatures within the mix while providing an optimal blend of large and small stones. This gives every finished road its homogenous look and long-lasting quality.

The Dynapac MF2500 IMIX is engineered around efficiency and robust day-to-day performance. When in operation, the augers in the hopper push large, inactive particles from the colder outer sections to the material hopper and towards the middle of the conveyor, where they join the main flow. Once transported to the top by the belt, the material is split by a flow divider into two streams. Before leaving the main conveyor, the material streams are again mixed and blended at the end of the conveyor by an auger mixing system. This unique arrangement helps equalize the temperatures within the mix while blending large and small stones. The result: quality, long-lasting roads that always look their best.

Flexibility is a must for any paving project. That’s why with the Dynapac MF2500 IMIX, both cold and non-segregated mix can be fed without engaging the MX Stage 2. When the MX Stage 2 is lifted, the throughput can go up from 1000 t/h to 4000t/h (2000 t/h with Swing conveyor attached). Among the many advantages of this function is increased throughput for cold material like RCC which is normally paved in thick layers and requires a lot of material.

Efficiency and convenience should be a part of every job, which is why the Dynapac MF2500 IMIX, comes with an optimized cleaning concept with an automatic spraying system for the belt an enlarged release agent hose and hose connections in the front and the back of the feeder. Additionally, the special heated scraper offers crews quick and easy cleaning after every use. Thanks to its unique design, it guarantees that residue and even particularly stick material does not get stuck on the machinery or fall on the floor. The heated scraper can also be switched off when cold material is conveyed.

Every mission should be completed with as few emissions as possible. That's why the Dynapac MF2500 is the feeder with the smallest ecological footprint in the market. Its low fuel consumption of less than 10l/hour helps reach sustainability goals while saving at the same time. The reduced number of parts also saves on replacement and general wear & tear. And with Dynapacs long-lasting belt concept, all replacements can be planned and scheduled conveniently and predictably.

Operators are behind the wheel of any project. That's why their comfort and safety are crucial. The Dynapac MF2500 puts the operator in focus with intuitive features like a simple-to-operate UNI panel, distance control- and material sensors, as well as the handy SwingAssist function. The Swing App System can now be brought on hydraulically without the aid of a crane or additional mounting assistant tools. The liftable platform offer excellent visibility, while moving the operator away from asphalt fumes.

Ultime notizie di OnSite News

Earthmoving Machinery

25/11/2024

Prinoth Unveils Expanded Production Facility in Granby, Canada

Prinoth held an event to announce the official opening of it...

Logistics

22/11/2024

Sarens acquires additional SCHEUERLE SPMT K24 modules

renowned for its expertise in crane rental services, heavy l...

Equipments

21/11/2024

SITECH partners with Royal Engineers to create poppy and demonstrate tech offering

The demostration involved creating a ground-level poppy desi...

Earthmoving Machinery

20/11/2024

Strong and stable RA30 trucks carry the weight at New Caledonian mine

Three Rokbak RA30 trucks are delivering exceptional durabili...

Lifting

20/11/2024

Tadano AC 7.450-1 Performs Double Duty in Wisconsin

A cost-saving and versatile solution was already on site - a...

Lifting

11/11/2024

Tadano AC 7.450-1 all terrain crane for the Victoria Tower in Mannheim

Tadano AC 7.450-1 all terrain crane lifts cooling unit to to...

Altri International

International

27/11/2024

Home of Volvo Construction Equipment’s pioneering articulated haulers advances to Climate Efficient Site

As one of the construction industry’s most active drivers of...

International

26/11/2024

Mota-Engil orders 10 Liebherr railroad excavators for a major project in West Africa

The Portuguese construction company Mota-Engil has once agai...

International

25/11/2024

New Grove GMK3060L-1 drives busy schedule for Mann Crane Hire

• Mann Crane Hire selected the GMK3060L-1 for its class-lead...

International

25/11/2024

Prinoth Unveils Expanded Production Facility in Granby, Canada

Prinoth held an event to announce the official opening of it...

International

23/11/2024

GPMat International takes delivery of two Raimondi T147s residential development in the South of France

- Official agent of France expands its product lineup with t...

International

22/11/2024

Sarens acquires additional SCHEUERLE SPMT K24 modules

renowned for its expertise in crane rental services, heavy l...