Home \ International \ EcoSheetPile Plus range from ArcelorMittal

EcoSheetPile Plus range from ArcelorMittal

12/07/2022

Pubblicato da Redazione

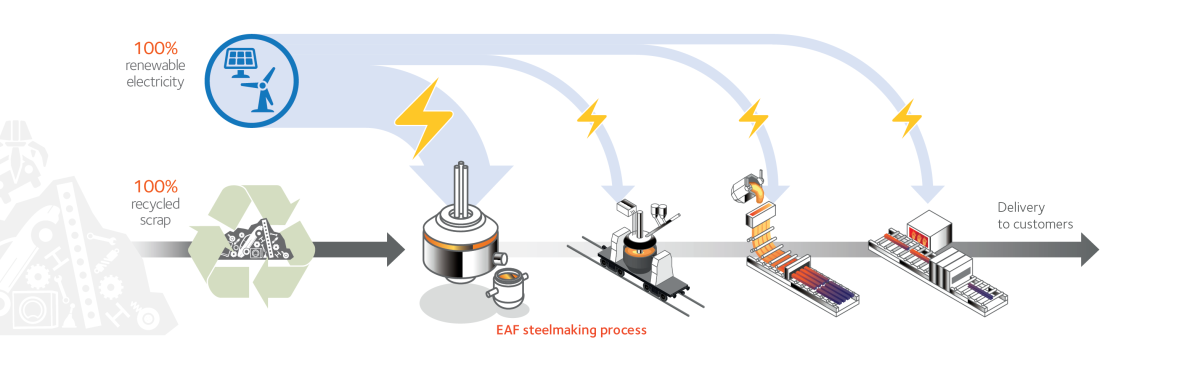

EcoSheetPile Plus products are made of 100% recycled material and 100% renewable energy.

ArcelorMittal has set another milestone on its way to the targeted climate neutrality in 2050. With the EcoSheetPile Plus range, ArcelorMittal Europe - Long Products will present steel sheet piles with a significantly reduced CO2 footprint at Bauma from October 24 to 30 in Munich (booth: A5-338). EcoSheetPile Plus products are already being used successfully in some major European infrastructure projects.

The EcoSheetPile Plus range of steel sheet piles are part of ArcelorMittal's XCarb recycled and renewably produced steel. The products are made in an electric arc furnace from 100% recycled material and are manufactured using 100% renewable energy from wind and solar sources. Certified by a dedicated Environmental Product Declaration (EPD), production of the EcoSheetPile Plus range generates only 370 kg of CO₂-eq. per ton of steel produced. By comparison, the average CO₂ emissions in the global steel industry for all production routes (conventional and electric) in 2020 were approximately 2.3 tons of CO₂-eq. per metric ton of steel products produced. In addition, an independently issued certificate of origin for the renewable electricity is included.

"The construction industry is one of the most challenging industry segments in terms of decarbonization. Regulations are becoming stricter, especially in the public sector. New projects are only approved if the CO₂ footprint meets the requirements," said Tapas Rajderkar, Chief Marketing Officer of ArcelorMittal Europe Long Products. "Some countries such as the Netherlands have started integrating environmental criteria into their tendering processes for new public infrastructures. The environmental performance of the different bids are fairly assessed and monetised, therefore giving an advantage to more sustainable solutions. We are proud to be the world’s leading producer of hot rolled steel sheet piles, as well as being an industry leader in innovating and offering sheet pile products with a significantly reduced CO2 footprint.”

Following its own Net Zero strategy and in accordance with client requirements, ArcelorMittal is already successfully using the steel sheet piles of the EcoSheetPile Plus range in several major European projects; for example, in the construction of a new fishing terminal in the port of Egersund, Norway. There, 2,200 tons of AS 500 straight-web sheet piles are being erected to form large circular cells structures. They will be filled with the sands dredged on-site to increase the draught of the port and eliminate transport emissions.

The CO2 footprint of a new quay wall at Ribécourt, on the upcoming Seine-Nord Europe canal in France will be significantly reduced thanks to the EcoSheetPile™ Plus range. The new waterway will connect French waterways with the Northern Europe network and drive water transport instead of road transport in France: Some barges carry as much cargo as 220 trucks. ArcelorMittal's HZ®/AZ® combined wall system is being used in the construction of a 200-meter quay wall. A total of 910 t of HZ 880M A-12 king piles and AZ 13-770 intermediate sheet piles are being used. Once completed, the Ribécourt quay will be used for the delivery of construction materials for the further canal construction.

At Bauma, visitors can also discover what the future holds for “Smart Sheet Piles”. These innovative sheet piling solutions – for example, installed in quay walls, flood protection walls or bridges – collect data in real time and transmit it remotely. This provides an efficient, controlled and automatised monitoring of the structures, helping to reach a cost-effective preventive maintenance. Last but not least, the increased safety aspect plays a major role. Alarm systems can be used to detect potential incidents earlier and help prevent floods for example. "A live demonstration of the technical concept of smart sheet piles will be the centerpiece of our stand at Bauma. We strongly believe in the benefits of this innovation for infrastructure stakeholders.", said Tapas Rajderkar.

Ultime notizie di OnSite News

Earthmoving Machinery

25/11/2024

Prinoth Unveils Expanded Production Facility in Granby, Canada

Prinoth held an event to announce the official opening of it...

Logistics

22/11/2024

Sarens acquires additional SCHEUERLE SPMT K24 modules

renowned for its expertise in crane rental services, heavy l...

Equipments

21/11/2024

SITECH partners with Royal Engineers to create poppy and demonstrate tech offering

The demostration involved creating a ground-level poppy desi...

Earthmoving Machinery

20/11/2024

Strong and stable RA30 trucks carry the weight at New Caledonian mine

Three Rokbak RA30 trucks are delivering exceptional durabili...

Lifting

20/11/2024

Tadano AC 7.450-1 Performs Double Duty in Wisconsin

A cost-saving and versatile solution was already on site - a...

Lifting

11/11/2024

Tadano AC 7.450-1 all terrain crane for the Victoria Tower in Mannheim

Tadano AC 7.450-1 all terrain crane lifts cooling unit to to...

Altri International

International

27/11/2024

Home of Volvo Construction Equipment’s pioneering articulated haulers advances to Climate Efficient Site

As one of the construction industry’s most active drivers of...

International

26/11/2024

Mota-Engil orders 10 Liebherr railroad excavators for a major project in West Africa

The Portuguese construction company Mota-Engil has once agai...

International

25/11/2024

New Grove GMK3060L-1 drives busy schedule for Mann Crane Hire

• Mann Crane Hire selected the GMK3060L-1 for its class-lead...

International

25/11/2024

Prinoth Unveils Expanded Production Facility in Granby, Canada

Prinoth held an event to announce the official opening of it...

International

23/11/2024

GPMat International takes delivery of two Raimondi T147s residential development in the South of France

- Official agent of France expands its product lineup with t...

International

22/11/2024

Sarens acquires additional SCHEUERLE SPMT K24 modules

renowned for its expertise in crane rental services, heavy l...