Home \ International \ Hamm HD+ 90i PH tandem roller: environment-friendly hybrid technology comes as standard

Hamm HD+ 90i PH tandem roller: environment-friendly hybrid technology comes as standard

18/05/2018

Pubblicato da Redazione

Hamm HD+ 90i PH tandem roller: environment-friendly hybrid technology comes as standard

In spring 2018, Hamm will present the new HD+ 90i PH tandem roller with hybrid power train. Here, Hamm is combining a conventional internal combustion engine with a hydraulic accumulator: the diesel engine covers the base load while the hydraulic accumulator meets peak loads. In 2017, the innovative roller demonstrated the effectiveness of the concept on many construction sites: users were extremely happy because they made significant savings in fuel, operating costs and expenditure on maintenance while still achieving the same compaction performance.

Hybrid solutions combine different technologies in a single system – in the case of cars, at the present time this generally means an internal combustion engine and an electric motor. Hamm, the innovation pioneer, has instead combined an internal combustion engine with a hydraulic system for the tandem roller. This has enabled Hamm to become the first roller manufacturer to develop a series production-ready machine, the 9-t HD+ 90i PH.

Hybrid power train: maximum performance despite a smaller engine

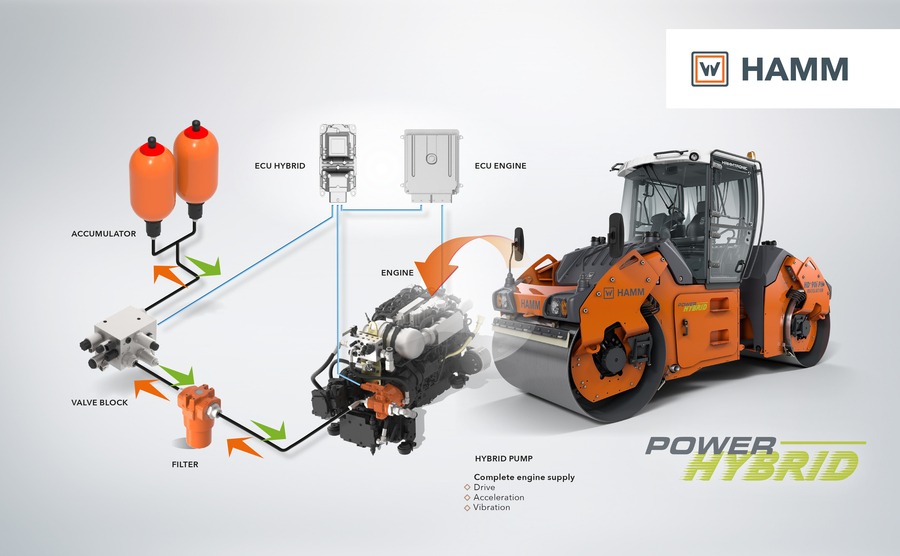

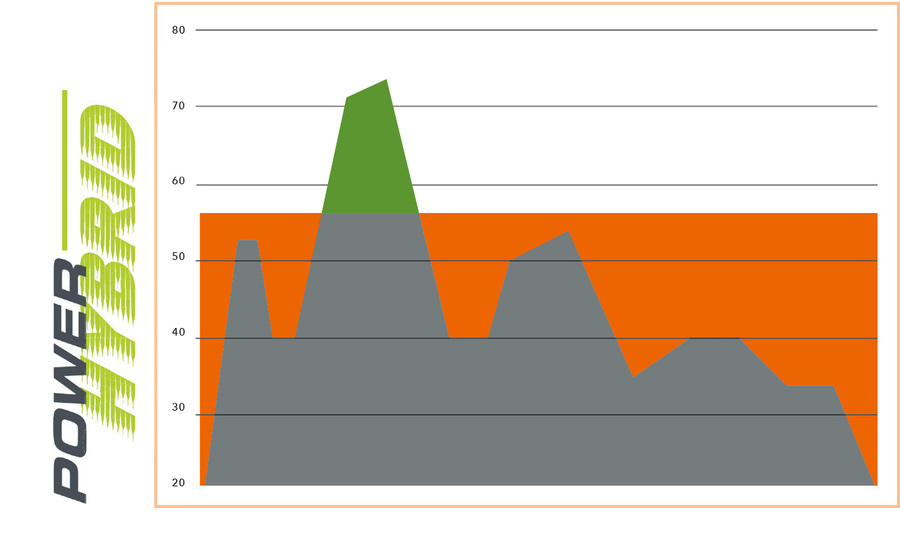

The underlying concept is based on the realisation that although the maximum load is called for regularly while compacting, it is always just for a few seconds at a time. This typically occurs when starting up or activating the vibration or oscillation for example. All other compaction tasks call for significantly less power. This is the reason why Hamm has equipped the power hybrid roller with a smaller diesel engine in combination with a hydraulic accumulator to satisfy the load peaks.

The hydraulic system works rather like a pumped storage power station: as soon as the power demand falls below the maximum load of the internal combustion engine, a pump fills the hydraulic accumulator. If a lot of power is called for, the hydraulic system functions as an auxiliary drive, able to supply a maximum short-term load of up to 20 kW. Following this the cycle begins afresh with the refilling of the accumulator. The principle functions splendidly because the maximum power is usually only called up for a matter of seconds. Afterwards there is sufficient time to replenish the accumulator.

This technology allows the roller to deliver the same power while equipped with a smaller diesel engine. Two other components of the HD+ 90i PH also help to ease the load on the diesel engine: an efficiency-optimised electric fan drive and an efficient start-stop system. This means that for the HD+ 90i PH a 55.4 kW output engine suffices - instead of the 85 kW unit in the conventional version.

Significantly quieter and with lower maintenance overheads

During 2017, the 9-t roller with hybrid power train was put through its paces on numerous construction sites the length and breadth of Europe. It proved its worth in every respect. Handling and maintenance are simplified for example, because the smaller engine does not require an SCR catalytic converter and thus no AdBlue. In addition, the roller is markedly quieter than its bigger-engined sibling. This aspect was well-received everywhere – including when compacting the binder and surface courses on the A 93 motorway in Bavaria. A Strabag team there reported no differences in compaction performance and quality compared to conventionally powered 9-t rollers - but everyone praised the lower noise emission thanks to the modified engine output.

Less fuel, but 100 % compaction power

The power hybrid roller was put to work with the Swedish construction company NCC over a number of months in 2017, racking up well over 500 operating hours in the process. Analyses revealed two important findings: Firstly, the PH roller invariably delivered the same compaction performance as its sibling model without hybrid technology. At the same time, NCC reported fuel savings of around 15%. This aspect was essential for the environmentally-conscious Swedes because the CO2 emissions are also markedly reduced.

Proven on city and country roads

Trials in France also yielded gratifyingly positive results: The French construction company Eiffage put the HD+ 90i PH to work for a number of weeks on widely differing sites in the south-west of France. The spectrum ranged from urban projects to the renovation of rural roads involving the compaction of widely differing asphalt types. Two experienced roller drivers put the new machine through its paces. They both agreed that the reduced interior noise level made it an extremely pleasant driving experience. Otherwise they could detect no difference to the 85 kW roller in respect of driving and compaction.

And when it comes to performance, the people at Eiffage are convinced by the hybrid concept: all sites were monitored by a team from the laboratory. The evaluations showed that the degree of compaction on all projects was as good as the degree of compaction of the conventional HD+ 90ii.

Available in many variants

The number of standard variants of the HD+ 90i PH power hybrid roller offered by Hamm has by now grown to 6: with double vibration (VV), double vibration with split drum (VV-S), one oscillation and one vibrating drum (VO), one oscillation and one split vibrating drum (VO-S), as a combi roller (VT) and as a combi roller with split vibrating drum (VT-S).

Ultime notizie di Wirtgen Macchine

Earthmoving Machinery

21/11/2024

Kleemann: New compact crusher used for recycling

Impact crusher MOBIREX MR 100i NEO impresses during operatio...

Road Machinery

04/11/2024

Wirtgen: Widening of the Ruta 5 highway from Montevideo to the Brazilian Border

Efficient concrete paving solutions from Wirtgen ensure the...

Road Machinery

31/10/2024

Wirtgen: Concrete paving with inset slipform pavers

Wirtgen has been offering machines for inset slipform paving...

Earthmoving Machinery

28/10/2024

Kleemann: Andesite processing in Indonesia

A MOBICAT MC 120 PRO and a MOBISCREEN MSS 802 EVO are deploy...

Earthmoving Machinery

24/10/2024

Benninghoven's REVOC system proven in practice

The REVOC Retrofit solution has been installed at an existin...

Road Machinery

01/10/2024

The Wirtgen Group at Paving Expo 2024

The Wirtgen Group presents groundbreaking technologies at Pa...

Altri International

International

23/11/2024

GPMat International takes delivery of two Raimondi T147s residential development in the South of France

- Official agent of France expands its product lineup with t...

International

22/11/2024

Sarens acquires additional SCHEUERLE SPMT K24 modules

renowned for its expertise in crane rental services, heavy l...

International

22/11/2024

Five WOLFF cranes modernize Oslo’s Ulven district

With a total of five WOLFF cranes of type 7534.16 Clear, Wol...

International

21/11/2024

Kleemann: New compact crusher used for recycling

Impact crusher MOBIREX MR 100i NEO impresses during operatio...

International

21/11/2024

SITECH partners with Royal Engineers to create poppy and demonstrate tech offering

The demostration involved creating a ground-level poppy desi...

International

20/11/2024

Strong and stable RA30 trucks carry the weight at New Caledonian mine

Three Rokbak RA30 trucks are delivering exceptional durabili...