Home \ International \ Hydra-Slide systems in Singapore

Hydra-Slide systems in Singapore

13/10/2017

Pubblicato da Redazione

Yu Sin Engineering Work Pte Ltd utilized a Hydra-Slide HT300 Heavy Track hydraulic skidding system and TT900-10 engineered Turntable to rotate a tunnel-boring machine (TBM) at a major subway infrastructure project in

Yu Sin Engineering Work Pte Ltd utilized a Hydra-Slide HT300 Heavy Track hydraulic skidding system and TT900-10 engineered Turntable to rotate a tunnel-boring machine (TBM) at a major subway infrastructure project in Singapore.

The site is part of the landmark Gardens By The Bay MRT Station project, a future underground Mass Rapid Transit station on the Thomson-East Coast Line in Marina South.

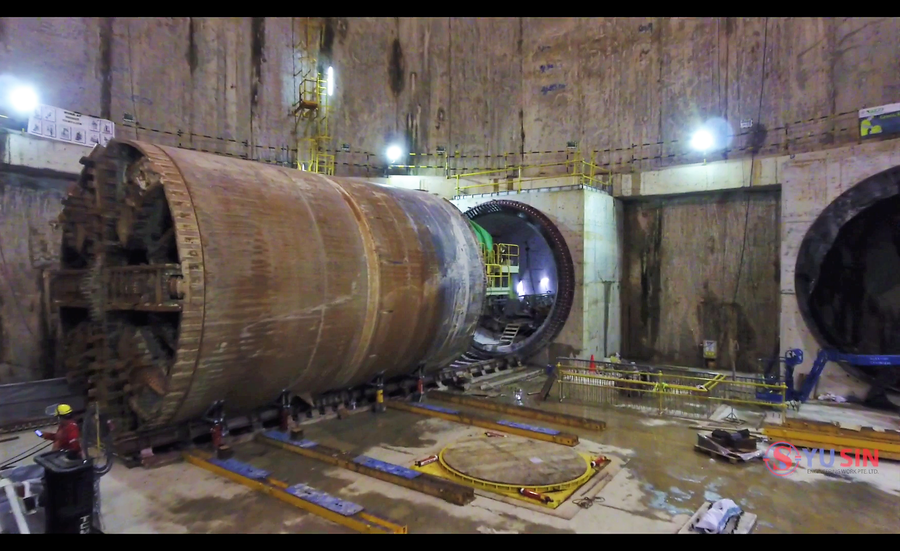

The TBM, manufactured by Hitachi Zosen Corporation, measured 22ft. (6.7m) in diameter and weighed 570 ton (520 tonne) It had completed an initial 2,225ft (679m) tunnel—the HT300 was used during the initial assembly and then at multiple other stages of the project. Now the TBM needed to be repositioned to begin its next boring assignment. The HT300 and TT900 combined to move and rotate the TBM in its entirety, 100 ft. (30m) underground. After two days of preparation work and planning, the actual rotation was completed in just one hour by skidding it onto the turntable, jacking down and rotating 180 degrees.

Jefferson Yee, general manager, Yu Sin Engineering Work Pte Ltd, said: “Initially the plan was to dismantle and re-launch [the TBM], but this would have taken a long time and we wanted to explore the option of a U-turn. After consulting with Hydra-Slide on the technical possibilities we proceeded with the alternative option, which resulted in a huge time savings.”

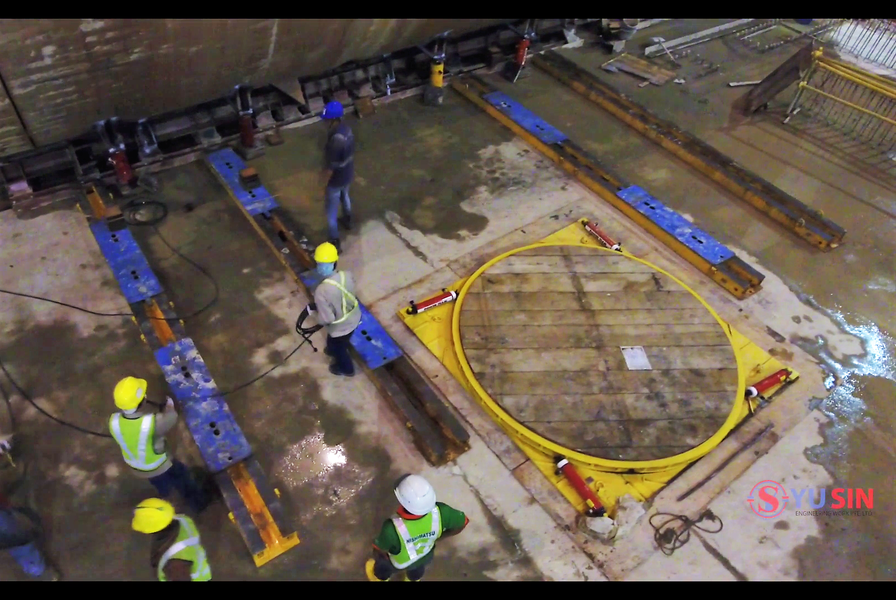

Prior to the rotation, the HT300 slid the TBM 40 ft. (12m) using 4 rails and four push cylinders to increase the HT300’s overall capacity. The system’s standard track lengths are 10ft. and 19ft. (3m and 6m) but Hydra-Slide can customize track lengths to suit almost any requirement. The tracks are connected by a simple lug and pin set and can be leap-frogged to slide longer distances.

The HT300 remained in place while the rotation was completed in one continuous motion, with the Turntable pus cylinders automatically resetting into ratchets after each push. The TT900, which had already been lowered into the shaft using a 250-ton capacity crawler crane, is more commonly used to turn transformers or generators during handling or installation, but it is suited to rotation of any heavy or oversized loads and Yee reported that it demonstrated its versatility and reliability.

He said: “We were familiar with the HT300 after the first sliding operation, but the TT900 proved to be just as fast, safe and easy to operate.”

The TT900-10, ordered by Yu Sin this spring, is a modification of Hydra-Slide’s TT500-10, designed to accommodate extra cylinders and rotating force. It was shipped to Singapore in an open-top container via sea freight.

Janine Smith, vice president at Hydra-Slide explained: “It is a simple system to operate. We have designed our Turntables with the same safety principles as our skidding systems – there are no winch lines or holdbacks required, the push cylinders automatically reset into specially designed ratchets on the side of the turntable, and there is no manual handling of any components required during operation. We spoke with the crew in Singapore when a question arose but they did not require any training on the product turntable. To the best of our knowledge, it is the first time the turntable has been used underground on a tunneling project; Yu Sin should be applauded for their pioneering utilization of the equipment. We see our equipment providing great potential for cost savings and increased efficiency in future TBM projects.”

The HT300 skid system and TT900 turntable are a cost-effective, accurate and safe method for moving, loading, unloading or rotating all types of heavy loads. Engineered ‘ratchet track’ designs enable continuous movement and automatic resetting of push cylinders without personnel being nearby during a move. The HT300 has a total height of only 7in. (180mm) and the TT900 is only 6in. (150mm). This saves jacking time and is ideal for working in confined spaces.

The tunnel boring is scheduled to complete by end of 2017.

Ultime notizie di OnSite News

Logistics

22/11/2024

Sarens acquires additional SCHEUERLE SPMT K24 modules

renowned for its expertise in crane rental services, heavy l...

Equipments

21/11/2024

SITECH partners with Royal Engineers to create poppy and demonstrate tech offering

The demostration involved creating a ground-level poppy desi...

Earthmoving Machinery

20/11/2024

Strong and stable RA30 trucks carry the weight at New Caledonian mine

Three Rokbak RA30 trucks are delivering exceptional durabili...

Lifting

20/11/2024

Tadano AC 7.450-1 Performs Double Duty in Wisconsin

A cost-saving and versatile solution was already on site - a...

Lifting

11/11/2024

Tadano AC 7.450-1 all terrain crane for the Victoria Tower in Mannheim

Tadano AC 7.450-1 all terrain crane lifts cooling unit to to...

Earthmoving Machinery

08/11/2024

Terapro Construction and Rokbak announce distribution agreement

Terapro Construction will now supply Rokbak articulated haul...

Altri International

International

23/11/2024

GPMat International takes delivery of two Raimondi T147s residential development in the South of France

- Official agent of France expands its product lineup with t...

International

22/11/2024

Sarens acquires additional SCHEUERLE SPMT K24 modules

renowned for its expertise in crane rental services, heavy l...

International

22/11/2024

Five WOLFF cranes modernize Oslo’s Ulven district

With a total of five WOLFF cranes of type 7534.16 Clear, Wol...

International

21/11/2024

Kleemann: New compact crusher used for recycling

Impact crusher MOBIREX MR 100i NEO impresses during operatio...

International

21/11/2024

SITECH partners with Royal Engineers to create poppy and demonstrate tech offering

The demostration involved creating a ground-level poppy desi...

International

20/11/2024

Strong and stable RA30 trucks carry the weight at New Caledonian mine

Three Rokbak RA30 trucks are delivering exceptional durabili...