Home \ International \ LR 1350/1 crawler crane involved in rotary kiln construction

LR 1350/1 crawler crane involved in rotary kiln construction

23/11/2017

Pubblicato da Redazione

The HeidelbergCement AG cement works in Schelklingen, Baden-Württemberg, has invested in a new rotary kiln system 68 metres in length. The main challenge in the project was to hoist the five components of the

The HeidelbergCement AG cement works in Schelklingen, Baden-Württemberg, has invested in a new rotary kiln system 68 metres in length.

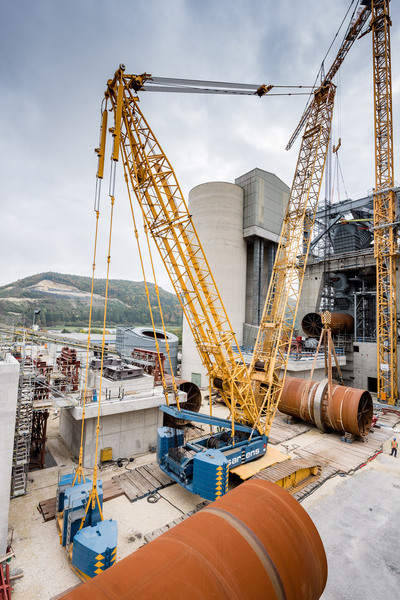

The main challenge in the project was to hoist the five components of the rotary kiln up to a height of 11 metres in a restrictive space. A Liebherr LR 1350/1 crawler crane from Belgian crane and heavy haulage contractor Sarens managed the job with aplomb. Furthermore a new Liebherr mobile crane is on the way to the Australian branch of the company. The new 8-axle LTM 1450-8.1 was ordered as a result of good past experience with crane manufacturer Liebherr.

The cement works is replacing its two existing rotary kilns to meet more stringent EU directives relating to emissions. Initially there were plans to use a 600-tonne class crane as a result of the planned component weights. However, due to the restricted space and the storage capacity in the plant, it was only possible to use a 350-tonne class crane. Sarens received the order to hoist the various rings using its LR 1350/1. The Belgian crane contractor set up the 350-tonne crane with a 42-metre main boom, a 27-metre derrick boom, as well as 85 tonnes of superstructure ballast and 75 tonnes of suspended ballast. After hoisting the components weighing up to 144 tonnes, the crane had to move around 20 metres on a specially prepared track so that the load could be positioned precisely for the installation work.

As soon as all five pipe sections of the rotary kiln had been positioned, they were aligned and welded together by fitters from Thyssen-Krupp. The finished rotary kiln ultimately had a net weight of 452 tonnes and was finished with refractory cladding so that in the future it will be capable of producing around 4500 tonnes of clinker every day. This clinker is then ground into cement.

Sarens is a leading global crane and heavy haulage contractor which provides creative solutions to challenges in the everyday heavy haulage and transport business. With more than 100 companies in 63 countries, Sarens is a global player with a fleet of around 1500 mobile and crawler cranes and currently employs around 4400 people.

Ultime notizie di Liebherr Italia

Lifting

19/11/2024

Liebherr Tower Cranes and John Paul Construction celebrate 50 years of partnership

Irish construction company John Paul Construction is celebra...

Lifting

29/10/2024

Wertz-Autokrane takes delivery of Liebherr LTM 1110-5.2 mobile crane

– The new 110-tonne crane complements the Wertz crane fleet...

Lifting

23/10/2024

New Liebherr mobile cranes for Scotland

To mark its 20th anniversary, Stoddart Crane Hire gave itsel...

Lifting

17/10/2024

German Federal Agency for Technical Relief places its trust in Liebherr compact cranes

The German Federal Agency for Technical Relief (THW) placed...

Lifting

14/10/2024

S.A.S Group expands Liebherr crane fleet

S.A.S Group expanded its Liebherr crane fleet with LTM 1300-...

Lifting

04/10/2024

Liebherr’s mobile construction crane range is expanding

MK 120-5.1, now available to order, is an agile five-axle mo...

Altri International

International

23/11/2024

GPMat International takes delivery of two Raimondi T147s residential development in the South of France

- Official agent of France expands its product lineup with t...

International

22/11/2024

Sarens acquires additional SCHEUERLE SPMT K24 modules

renowned for its expertise in crane rental services, heavy l...

International

22/11/2024

Five WOLFF cranes modernize Oslo’s Ulven district

With a total of five WOLFF cranes of type 7534.16 Clear, Wol...

International

21/11/2024

Kleemann: New compact crusher used for recycling

Impact crusher MOBIREX MR 100i NEO impresses during operatio...

International

21/11/2024

SITECH partners with Royal Engineers to create poppy and demonstrate tech offering

The demostration involved creating a ground-level poppy desi...

International

20/11/2024

Strong and stable RA30 trucks carry the weight at New Caledonian mine

Three Rokbak RA30 trucks are delivering exceptional durabili...