Home \ International \ New pump drive from Stiebel

New pump drive from Stiebel

04/05/2017

Pubblicato da Redazione

Under tough conditions, such as those encountered in mining and open cast mining operations, high-performance machine and transmission solutions are needed that are both ecologically sustainable and

Under tough conditions, such as those encountered in mining and open cast mining operations, high-performance machine and transmission solutions are needed that are both ecologically sustainable and cost efficient at the same time. Hybrid or fully electric drive concepts are in increasing demand for such applications, because they offer reduced emissions coupled with excellent energy efficiency. To meet these challenges the experts at Stiebel Drive Technology employ high performance and individually adapted transmission solutions to realize a wide range of mobile hydraulic applications.

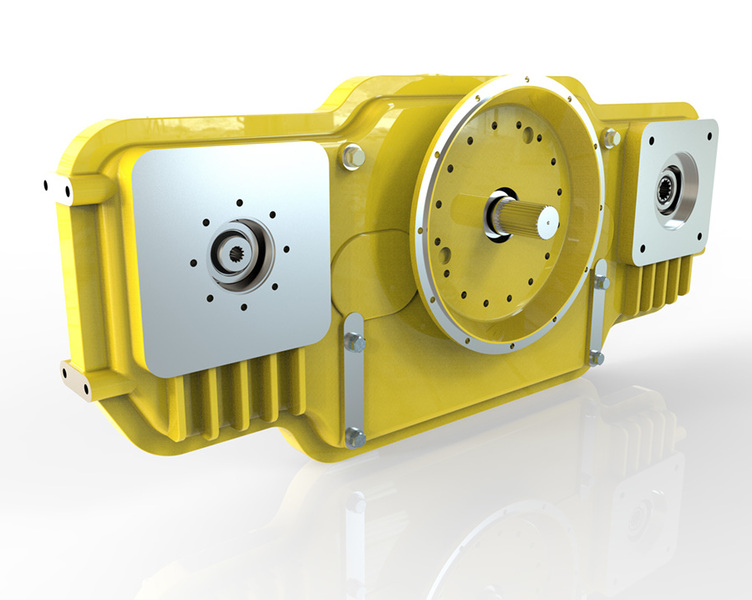

With the pump drive type 4395, the experts have now created a drive solution for mobile diesel-electric hybrid crushers. The transmission is part of the modular motor/transmission unit and makes an essential contribution to energy efficiency and the optimization of fuel consumption, thereby making operations particularly environmentally friendly. The Stiebel pump drive, specially developed for the field of crushing, has an input power of 940 HP (700 kW), a max. output power per pump shaft of 480 HP (360 kW), and ratios of between 1.0 and 0.67. An offset intermediate shaft offers a very large spacing between the power take-off shafts with an inline design. This allows large motor components up to SAE-0 to be attached in direct and through-drive mode, while simultaneously driving hydraulic units up to SAE-E on both sides of the output driveshafts.

The special benefit offered by this solution lies in the different drive modi, which can be selected in accordance with the specific requirements. In mode 1 the diesel engine and transmission operate to deliver an extra high level of power, necessary when crushing hard stone for instance. In this mode, power is delivered to the auxiliary equipment and a generator, which charges the energy storage unit. In the second drive mode the diesel engine is decoupled from the transmission and the drive is provided by the electric motor on the through-drive side. The electric motor is now powered by the energy storage unit. In comparison with the use of the diesel engine, the electric drive is particularly environmentally friendly because no exhaust gases are emitted. It furthermore offers greater efficiency and produces less waste heat, which has a positive effect on the cooling situation of the overall system.

A further drive mode can also be realized if a hydraulic drive motor is fitted to the power take offs. In addition to the diesel-electric hybrid solutions, the pump drive with drive-side clutch offers many more drive options. These have already been successfully proven many hundreds of times during practical operations across a range of different industries.

‘Smart’ electric drive for a range of different mobile hydraulic applications

The transmission experts at Stiebel also provide transmissions that are designed for the appropriate hydraulic power requirements and to which an electric motor can be directly fitted without a clutch being necessary in-between. These economically efficient solutions are in particular demand for all tunnel construction, deep-shaft mining and offshore applications, because they generate no emissions. The weight saving is a further benefit which significantly simplifies integration into engine compartments as they become more compact with advances in design. Stiebel is continuously working to develop new solutions which further advance the technology of hybrid to fully electric drive concepts.

Ultime notizie di

01/07/2021

The compact Sennebogen 613 E telescopic mobile crane proves its flexibility and safety in the mine

Südwestdeutsche Salzwerke AG welcomed a new Sennebogen 613 E...

07/11/2019

COMANSA presents its new 21LC1400 model

A new large-capacity Flat-Top crane

26/09/2017

Robbins Slurry TBM ramps up for Mumbai Metro Line 3

The first of two Slurry TBMs, a rebuilt 6.65 m (21.8 ft) dia...

23/09/2017

The world’s strongest rope for the German Zugspitzbahn

For walkers and winter visitors, there are two ways to ride...

21/09/2017

Modulift beams suspend full scale model fighter jet

Four Modulift spreader beams were used to suspend a full sca...

20/09/2017

A tunnel project with PSC Crane & Rigging

PSC Crane & Rigging, headquartered in Piqua, Ohio, supplied...

Altri International

International

23/11/2024

GPMat International takes delivery of two Raimondi T147s residential development in the South of France

- Official agent of France expands its product lineup with t...

International

22/11/2024

Sarens acquires additional SCHEUERLE SPMT K24 modules

renowned for its expertise in crane rental services, heavy l...

International

22/11/2024

Five WOLFF cranes modernize Oslo’s Ulven district

With a total of five WOLFF cranes of type 7534.16 Clear, Wol...

International

21/11/2024

Kleemann: New compact crusher used for recycling

Impact crusher MOBIREX MR 100i NEO impresses during operatio...

International

21/11/2024

SITECH partners with Royal Engineers to create poppy and demonstrate tech offering

The demostration involved creating a ground-level poppy desi...

International

20/11/2024

Strong and stable RA30 trucks carry the weight at New Caledonian mine

Three Rokbak RA30 trucks are delivering exceptional durabili...