Home \ International \ New Volvo excavators elevate customer productivity

New Volvo excavators elevate customer productivity

17/06/2024

Pubblicato da Ettore Zanatta

A new range of excavators from Volvo Construction Equipment (Volvo CE) show they have the edge with a modern makeover that takes customers into the future.

The newest models have been revamped to be more spacious and ergonomic than ever before as part of an ambitious design concept to help customers achieve outstanding results. The new range – thanks in large part to a new operator environment with improved human machine interface (HMI) – not only looks good but has been built to robustly respond to the challenges of today and tomorrow.

Kurt Deleu, Head of Product Management Excavators, says: “We have always been proud to lead the market with our innovative line of excavators, and now with this new range we are helping our customers get even more out of their machines. This modern design significantly improves the operator experience, allowing machine and human to deliver a powerful performance fit for the challenges of today’s worksites.”

First to be introduced in Europe and Turkey are the newest EC500, EC400 and EC230 crawler excavators – all of which benefit from the same impressive range of technologically advanced features and were unveiled at Volvo Days 2024 in Eskilstuna, Sweden. A stylish new operator environment provides even more space and comfort, with a coolbox to store items and USB and Bluetooth connections to charge mobile phones, play music and aid on-site communication. Furthermore, thanks to an improved HMI, a keyless engine start and an always-on camera, a productive working day can be carried out with ease and, above all, safety.

Better sealing also ensures less dust passes inside the cab, while improved heating, ventilation and air conditioning secures a superior air circulation and a reduced risk of fatigue. Together with lower noise levels and built-in sunscreen, the operator experience is now more comfortable than ever. The intelligent technology behind the new electro-hydraulic system enables sensors to monitor operator movements and send signals to command the enhanced main control valve. The result is smooth and precise movement of the excavator’s boom, bucket and other attachments, as well as more accurate digging and loading. Among a host of other efficiency-boosting features are a smart cooling system, engine speed regulation and engine pump optimization to further minimize energy consumption, as well as an auto power boost function to ensure an automatic setting of the system pressure. All of these extra features not only result in improved fuel efficiency but are a cost-effective boost to total cost of ownership (TCO).

The new excavators are made to help customers achieve more for less, and work with more precision and speed than ever before. Thanks to the new electro-hydraulic system and the automation of boom and bucket movements, operator fatigue is reduced and efficiency increased, enabling precise digging and shorter cycle times with minimal input. The advanced electric control joysticks and fully electric travel pedals provide lightning-fast response times, while the swing control, bucket angle control and a tilt bucket and tiltrotator control all help the operator maintain a precise cutting angle with just the press of a button.

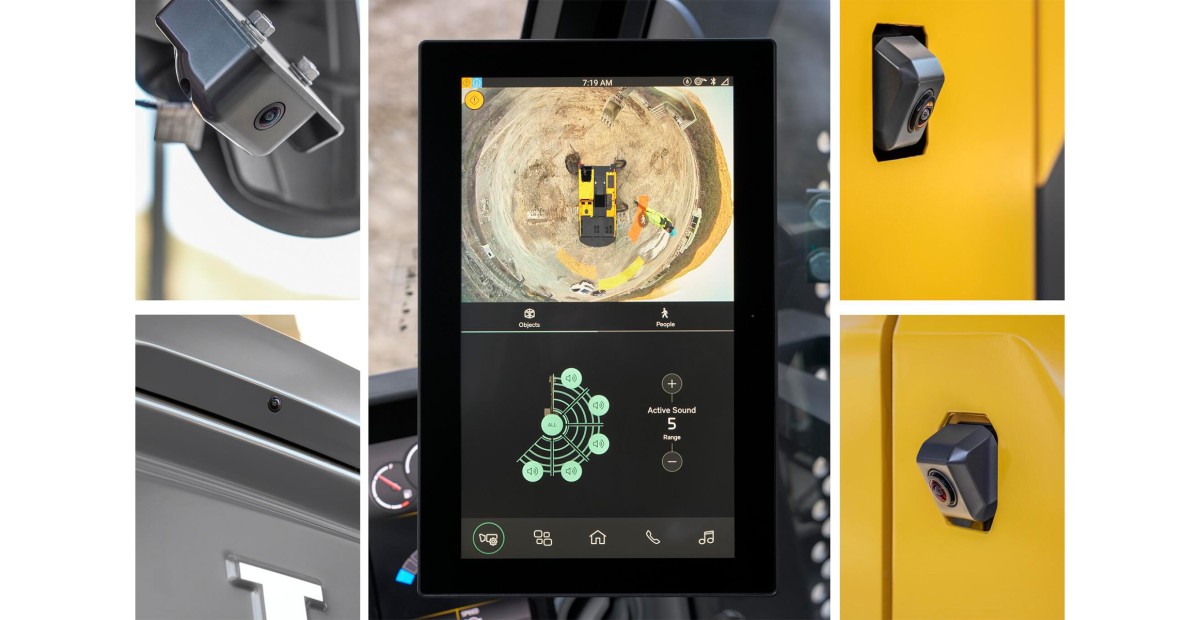

The opportunity to pre-set limits on the boom’s depth, height and swing ensures operators carry out their tasks to the highest possible standards of safety. This can help them to avoid overhead or underground hazards, such as power lines, pipes and cables, and walls or barriers – as well as, most importantly, any humans on site. Volvo Smart View with Obstacle Classification gives operators a 360° visibility of the machine’s surroundings, thanks to its camera and new radar detection system. Benefiting from deep learning technology, the feature alerts operators if objects or human beings are detected nearby or even far away. The radar’s reach can be easily pre-set on a high-definition screen, depending on the confinement of the work environment. Volvo excavators already boast some of the longest service intervals in the industry, with 1,000-hour engine oil, engine oil filters and fuel filter changes. But with these recent upgrades, servicing is improved still further with daily maintenance now safer and easier to achieve from the ground level.

The engine hood is now fully openable, the swing out condenser makes the radiator and oil cooler easier to inspect, a convenient shut-off valve prevents fuel leakage and fluid draining has been made simpler and more environmentally friendly. The new generation state-of-the-art functionality can be enhanced with the addition of Volvo CE’s pioneering range of smart solutions including Volvo Active Control, On-Board Weighing and Dig Assist 2D and 3D, which provide unrivalled machine guidance and control technology.

Ultime notizie di Volvo CE Italia

Earthmoving Machinery

19/09/2024

Volvo CE inaugurates new facilities to support production of electric wheel loaders in Arvika

The industry shift has taken another exciting leap forward a...

Components

26/06/2024

Operator connectivity with Volvo CE'"My Equipment" digital tool

"My equipment" is a new digital solution from Volvo Construc...

Equipments

10/06/2024

Innovative mobile charging solution from Volvo CE set to transform off-grid work

Volvo Construction Equipment (Volvo CE) is launching a new s...

Earthmoving Machinery

29/05/2024

Volvo CE: the catalogue of Product Carbon Footprint

Volvo CE empowers customers with industry’s most extensive c...

Earthmoving Machinery

17/05/2024

Volvo CE has taken a 22% ownership stake in VizaLogix

Volvo CE has taken a 22% ownership stake in VizaLogix, a US-...

Earthmoving Machinery

06/02/2024

Machines perfectly monitored with Volvo ActiveCare

With ActiveCare, Volvo monitors the condition of machines re...

Altri International

International

23/11/2024

GPMat International takes delivery of two Raimondi T147s residential development in the South of France

- Official agent of France expands its product lineup with t...

International

22/11/2024

Sarens acquires additional SCHEUERLE SPMT K24 modules

renowned for its expertise in crane rental services, heavy l...

International

22/11/2024

Five WOLFF cranes modernize Oslo’s Ulven district

With a total of five WOLFF cranes of type 7534.16 Clear, Wol...

International

21/11/2024

Kleemann: New compact crusher used for recycling

Impact crusher MOBIREX MR 100i NEO impresses during operatio...

International

21/11/2024

SITECH partners with Royal Engineers to create poppy and demonstrate tech offering

The demostration involved creating a ground-level poppy desi...

International

20/11/2024

Strong and stable RA30 trucks carry the weight at New Caledonian mine

Three Rokbak RA30 trucks are delivering exceptional durabili...