Home \ International \ Potain took center stage at Intermat Paris 2018

Potain took center stage at Intermat Paris 2018

08/05/2018

Pubblicato da Redazione

Manitowoc participated once more at one of the world’s biggest infrastructure and construction tradeshows, Intermat Paris, during which Potain celebrated its 90th anniversary and launched the Hup self-erecting crane range and an MDT 389, the largest

Manitowoc participated once more at one of the world’s biggest infrastructure and construction tradeshows, Intermat Paris, during which Potain celebrated its 90th anniversary and launched the Hup self-erecting crane range and an MDT 389, the largest of its CCS topless top-slewing tower cranes.Potain is also launched the 75 HPL winch for tower cranes and presented the upcoming Potain Cab-IN internal operator lift at the tradeshow.

“Potain is a name that is synonymous with the tower crane industry and is a vital part of the success of Manitowoc,” said Aaron Ravenscroft, executive vice president of Manitowoc. “This year, under the anniversary theme ‘Achieving Your Vision,’ attendees will see how we are celebrating the long success of the company and the vision of its founder, Faustin Potain, who started the business in 1928. “Faustin introduced the values of customer proximity, innovation and performance. Those values led to the brand’s success over the decades and are still very much alive today. Being in France, where the brand was born, makes Intermat the perfect place to celebrate this milestone, together with our customers and partners who are part of the success of Potain”, Ravenscroft continued.

Potain celebrated its 90th year with a “birthday” event at its booth, where visitors expected a look back at Potain’s history, cake, music and a festive atmosphere to commemorate the occasion.

Customer-inspired cranes

To affirm Potain’s commitment to its customers, Manitowoc displaywd two models from the Hup self-erecting crane range - a Hup 32-27 and a Hup 40-30 - and an MDT 389 CCS topless top-slewing tower crane. All three cranes were developed with significant customer input and participation. The cranes reflect the technologies and features that the lifting market needs most and they were developed with much more velocity to market than previous generations of cranes.

The Hup self-erecting crane range contains some of Potain’s most remarkable models of recent years. Having been out for just over a year, the cranes’ versatility and ease-of-use have already made them an international hit. The cranes have a maximum capacity of 4 t and a rear-slewing radius of only 2.25 m for the Hup 32-27, enabling them to be positioned closer to buildings - a major benefit when working in tight urban areas or job sites with restricted working quarters.

Despite being taller than the Igo 36, one of its predecessor models, the Hup cranes occupy the same footprint, making them ideal for space-restricted job sites. Three raised positions of the luffing jib, at 10°, 20° or 30° for the Hup 32-27, in addition to horizontal, provide unprecedented options for a self-erecting crane. With two height options for their telescopic masts and an exclusive new radio remote control with Potain’s Smart Set Up software, operators can maximize their efficiency to levels previously unseen.

The MDT 389 is the largest topless crane from the Potain line-up to feature the company’s Crane Control System (CCS), which is also available on all MDT and MD Potain top-slewing tower cranes and Grove mobile cranes. This user-friendly operating system offers owners the highest levels of comfort, flexibility and ergonomic control, and it reduces installation time compared to previous models. There are two versions of the Potain MDT 389, one with a 12 t maximum capacity and the other with a 16 t maximum capacity. Both have up to 75 m of jib available, and the 12 t version can lift 3.4 t at its jib end, while the 16 t version can handle 3.3 t.

The MDT CCS Topless concept enables complex, multi-crane installations, and the assembly, erection, transport and maintenance phases are shorter than previous generations of tower cranes. All of these features lead to a better return on investment for crane owners, and CCS has been proven to increase efficiency on the job site.

“With the recent updates in Potain design and production, we are confident that these cranes will improve efficiencies and expand lifting capabilities to a level not yet seen in Europe, all at a lower total cost of ownership for our customers,” Ravenscroft said. “We can’t wait to see such cranes benefit the development of the Grand Paris project, a 30 billion EURO infrastructure project that aims to transform Paris into a 21st Century city, confirming its rank among international megacities.”

New Potain components

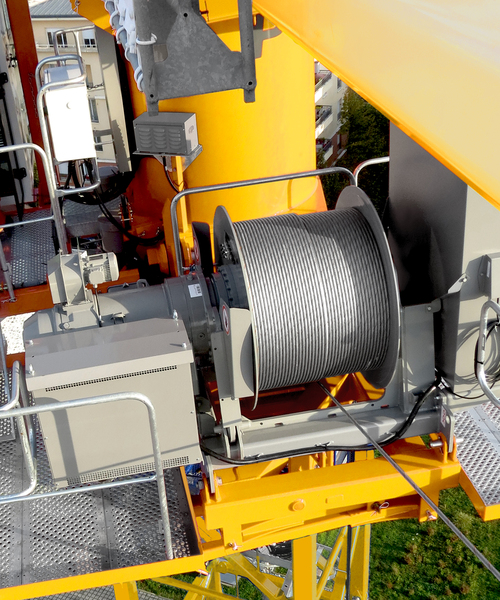

Manitowoc showcased key new innovations at Intermat, the first of which is the 75 HPL winch. The 75 HPL is suitable for all top slewing cranes. It comes in four versions, from 10 to 16 t capacity, making it adaptable to most work sites. Its increased hoisting speeds enable quick load handling and shorter hoisting cycles, resulting in increased productivity for customers. Temperature monitoring of the motor and reduction gear helps to increase service life, and for CCS cranes this can be displayed on the display inside the cab. What’s more, the new winch architecture makes components easy to access, giving quick access for servicing and checking reduction gear oil levels. Other features include a lower level of vibration and reduced noise levels, an optimized power network that automatically adapts to the electrical network, and smooth and precise operation thanks to new service break controls.

The second new product feature previewed at Intermat is the Potain Cab-IN, the company’s inside mast operator lift. Developed for Potain top slewing cranes in partnership with GEDA, an industrial elevator and construction lift manufacturer, the Potain Cab-IN allows for fast and easy travel to and from the cab, fits inside all K-mast systems and is compatible with all Potain bases/chassis. It also boosts cost efficiency, as it does not incur additional transportation costs or require extra storage space on the yard. The Potain Cab-IN will be released in late 2018 and meets French regulations that are set to be implemented in January 2019, as well as in the Netherlands and Scandinavian countries, where regulations require lifts on cranes from certain heights.

Furthermore, Manitowoc highlighted its remote crane diagnostic system, CraneSTAR Diag, at Intermat. CraneSTAR Diag is part of a new generation of remote maintenance support from Manitowoc. The powerful telematic device is available on all Potain CCS and MCT cranes and offered as an option on Hup cranes. Remote access to the crane’s operating and maintenance information reduces maintenance time allocation and potential downtime on site.

“Continuous improvement is deeply embedded in our culture, based on the principles of The Manitowoc Way,” concluded Ravenscroft. “We are now moving into a new phase of our growth, where customer engagement, new product development and aftermarket support will help us build on our leadership position. We have already been busy bringing new products and innovations to the market with the velocity that customers expect, and we plan to continue to do so for many more years to come.”

Ultime notizie di Manitowoc Cranes Group Italy

Lifting

06/11/2024

Dutch crane company receives one of Europe’s first Grove GMK4080L all-terrain cranes

Kraanverhuur Tholen has purchased a new Grove GMK4080L all-t...

Lifting

30/10/2024

Eight Potain cranes team up to construct Milan’s stunning new CityWave building

• CMB and Colombo Costruzioni – two of the most respected na...

Lifting

28/10/2024

Grove upgrades the GMK6400-1 to GMK6450-1

Grove responded to customer demand for a higher-capacity cra...

Lifting

18/10/2024

Manitowoc to launch major new product at bauma China 2024

• Manitowoc will announce a significant new crane introducti...

Lifting

07/10/2024

Manitowoc introduces new Potain Igo M self-erecting crane

The Potain Igo M 24-19 is a ideal choice for new home constr...

Lifting

01/10/2024

Fast delivery and ‘like new’ feel for Grove GMK5150L purchased by Q3 Heavy Lift

• The Dutch heavy lift company needed a 150 t addition to it...

Altri International

International

23/11/2024

GPMat International takes delivery of two Raimondi T147s residential development in the South of France

- Official agent of France expands its product lineup with t...

International

22/11/2024

Sarens acquires additional SCHEUERLE SPMT K24 modules

renowned for its expertise in crane rental services, heavy l...

International

22/11/2024

Five WOLFF cranes modernize Oslo’s Ulven district

With a total of five WOLFF cranes of type 7534.16 Clear, Wol...

International

21/11/2024

Kleemann: New compact crusher used for recycling

Impact crusher MOBIREX MR 100i NEO impresses during operatio...

International

21/11/2024

SITECH partners with Royal Engineers to create poppy and demonstrate tech offering

The demostration involved creating a ground-level poppy desi...

International

20/11/2024

Strong and stable RA30 trucks carry the weight at New Caledonian mine

Three Rokbak RA30 trucks are delivering exceptional durabili...