Home \ International \ Robbins TBM takes on Karstic Limestone below St. Louis

Robbins TBM takes on Karstic Limestone below St. Louis

23/05/2022

Pubblicato da Ettore Zanatta

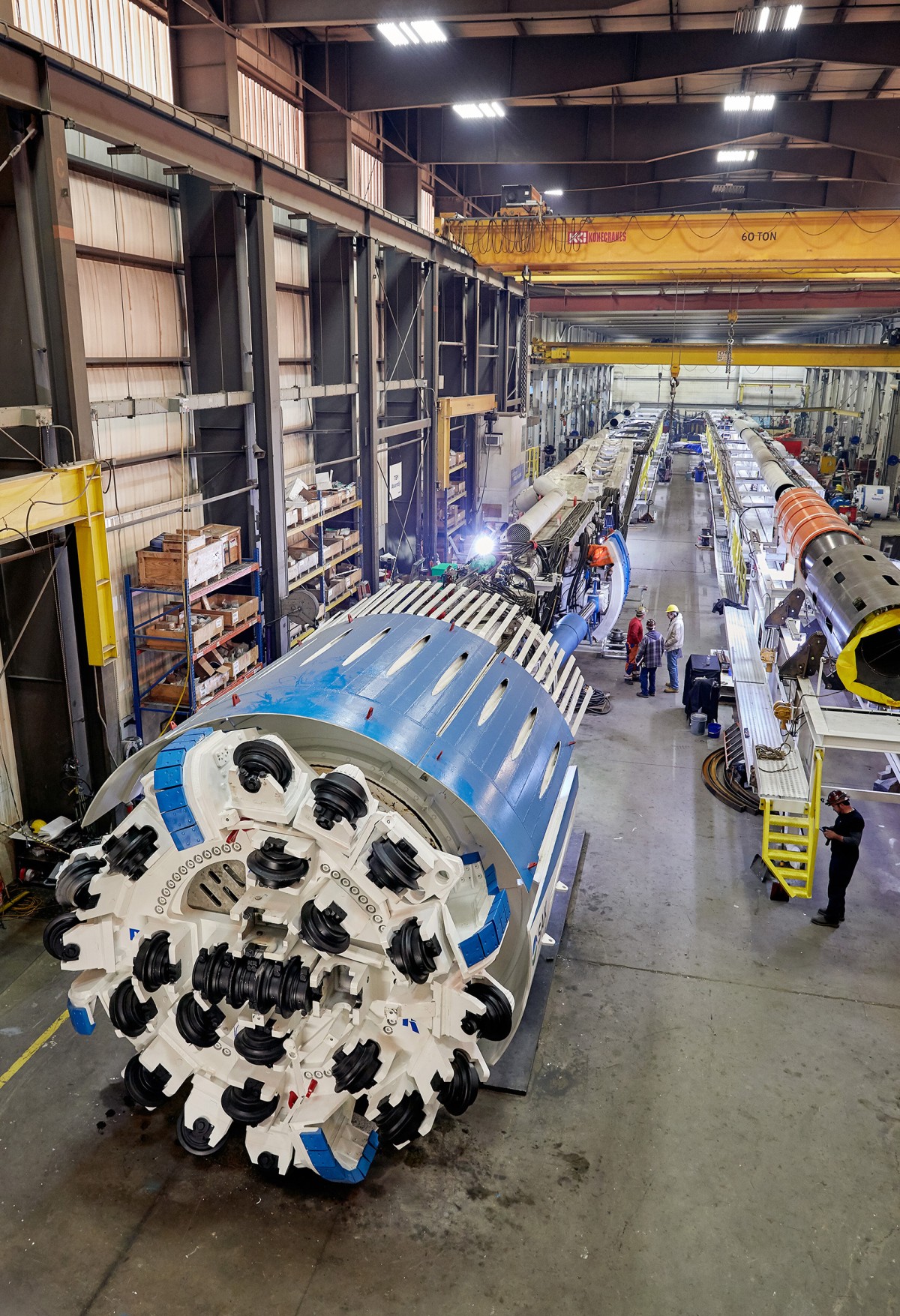

Missouri Main Beam launches at Jefferson Barracks Phase 2.

In Spring 2022, a specialized Robbins 4.1 m (13.5 ft) diameter Main Beam TBM launched in St. Louis, Missouri, USA, to complete a critical infrastructure tunnel for contractor SAK Construction. The machine, named “Mrs. Vera”, is boring Phase 2 of the Jefferson Barracks tunnel, a 3,050 m (10,000 ft) long tunnel in karstic limestone.

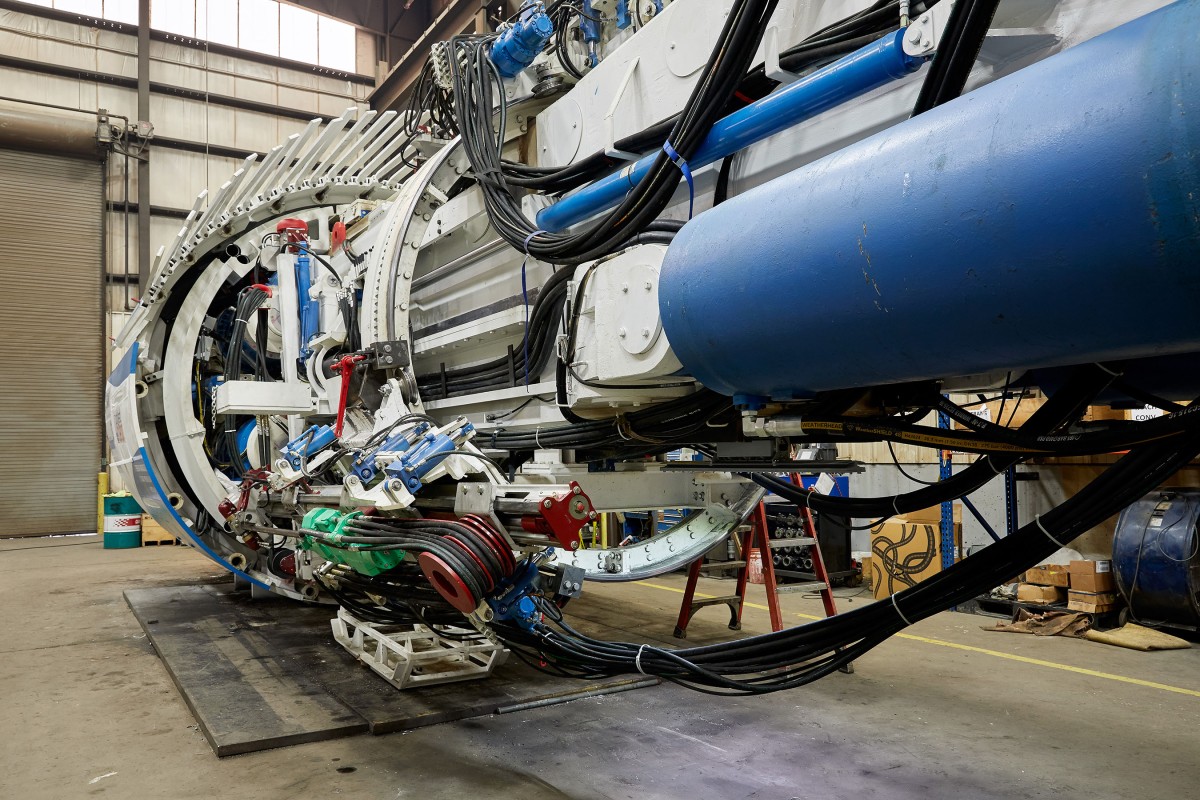

Designed to detect karst and other underground features, the unique machine comes equipped with enhanced 360-degree probe drilling capabilities, as well as versatile ground support options including McNally crown support, wire mesh, ring beam erector and roof drills. “The overall design of the machine is a good fit for our project, not only for the mining aspect but also for the capability to run two probe drills in multiple locations around the TBM,” said Brotherman Bragg, Project Superintendent for SAK Construction. “The challenges I anticipate during tunneling are mostly related to ground conditions. The area that we are tunneling in has a potential for karst features. The probe drills are our lifeline and with the two probe drills on the machine, I believe that we will find out what’s in front of us before we get there, giving us the ability to take care of potential problems.”

During Phase 1 of Jefferson Barracks, a rebuilt 3.35 m (11.0 ft) diameter Robbins Main Beam TBM hit challenging conditions about 2,400 m (7,900 ft) into tunneling. The machine encountered a large vertical feature along with flowing and unstable ground that required the TBM to remain in place. While various options including ground freezing were considered, they were ultimately deemed infeasible. A 62 m (205 ft) deep recovery shaft and 60 m (200 ft) long adit were built to stabilize the area and remove the machine in what would be an intensive and ultimately successful undertaking. After recovery of the machine, SAK Construction turned to Robbins for a solution to bore the remaining tunnel in what would become Phase 2 of the project. SAK and Robbins agreed to do extensive in-shop testing of the new, larger TBM to ensure there would be no unnecessary delays on site. The TBM was ultimately delivered a couple months late due to both COVID-related matters and the additional in-shop testing. SAK operational personnel and Robbins personnel were heavily involved in final assembly and testing procedures.

After arriving in St. Louis, the TBM was swiftly assembled and launched from the recovery shaft. “The Robbins Field Service techs have been excellent in their support, helping us assemble the machine, and troubleshoot the machine. Our challenges during the assembly and launch from the shaft were minimal – this is the fastest and most efficient assembly we’ve ever had on a machine. We assembled the TBM in four weeks, which was a huge hurdle,” said Bragg. “The overall design [of the TBM] is very functional and thus far in the early stages it seems to be mining very well,” continued Bragg. “So far, I’m very pleased with the machine and with the technicians.” Early indications were good, with the machine advancing 21 m (70 ft) in its first two shifts after launch.

The Jefferson Barracks project is a key component of MSD Project Clear, a massive USD $6 billion program undertaken by the Metropolitan St. Louis Water District to target water quality and wastewater concerns in the city and surrounding areas. The 5,400 m (17,800 ft) long, 2 m (7 ft) internal diameter Jefferson Barracks tunnel runs parallel to the Mississippi River and extends to the Lemay Wastewater Treatment Plant located at the confluence of the River des Peres and the Mississippi. The tunnel is slated for completion in Autumn 2023.

Ultime notizie di OnSite News

Earthmoving Machinery

25/11/2024

Prinoth Unveils Expanded Production Facility in Granby, Canada

Prinoth held an event to announce the official opening of it...

Logistics

22/11/2024

Sarens acquires additional SCHEUERLE SPMT K24 modules

renowned for its expertise in crane rental services, heavy l...

Equipments

21/11/2024

SITECH partners with Royal Engineers to create poppy and demonstrate tech offering

The demostration involved creating a ground-level poppy desi...

Earthmoving Machinery

20/11/2024

Strong and stable RA30 trucks carry the weight at New Caledonian mine

Three Rokbak RA30 trucks are delivering exceptional durabili...

Lifting

20/11/2024

Tadano AC 7.450-1 Performs Double Duty in Wisconsin

A cost-saving and versatile solution was already on site - a...

Lifting

11/11/2024

Tadano AC 7.450-1 all terrain crane for the Victoria Tower in Mannheim

Tadano AC 7.450-1 all terrain crane lifts cooling unit to to...

Altri International

International

27/11/2024

Home of Volvo Construction Equipment’s pioneering articulated haulers advances to Climate Efficient Site

As one of the construction industry’s most active drivers of...

International

26/11/2024

Mota-Engil orders 10 Liebherr railroad excavators for a major project in West Africa

The Portuguese construction company Mota-Engil has once agai...

International

25/11/2024

New Grove GMK3060L-1 drives busy schedule for Mann Crane Hire

• Mann Crane Hire selected the GMK3060L-1 for its class-lead...

International

25/11/2024

Prinoth Unveils Expanded Production Facility in Granby, Canada

Prinoth held an event to announce the official opening of it...

International

23/11/2024

GPMat International takes delivery of two Raimondi T147s residential development in the South of France

- Official agent of France expands its product lineup with t...

International

22/11/2024

Sarens acquires additional SCHEUERLE SPMT K24 modules

renowned for its expertise in crane rental services, heavy l...