Home \ International \ Stiebel Drive Technology’s drive solutions at Conexpo CON/AG 2017

Stiebel Drive Technology’s drive solutions at Conexpo CON/AG 2017

06/02/2017

Pubblicato da Redazione

The shift towards new mobile hydraulic applications goes hand in hand with sophisticated and

The shift towards new mobile hydraulic applications goes hand in hand with sophisticated and commercially effective systems which are capable of mastering the growing challenges under the toughest conditions. With their adaptable and high performance gearboxes, the specialists at Stiebel Drive Technologyare developing the appropriate technologies – ones that also score in terms of energy balance.

One convincing drive solution is the Stiebel type 4652 transfer gearbox which is used in mobile tracked drilling rigs for instance. The massive casing ribbing and the geometric offset of the drive/take-off shafts deliver an improved energy balance. This normally renders an additional oil cooler unnecessary. With its Pmax of 700 kW, T2max of 3300 Nm and maximum rotational speed nmax of 2500 min-1,sustainable and economical drilling operations are supported.

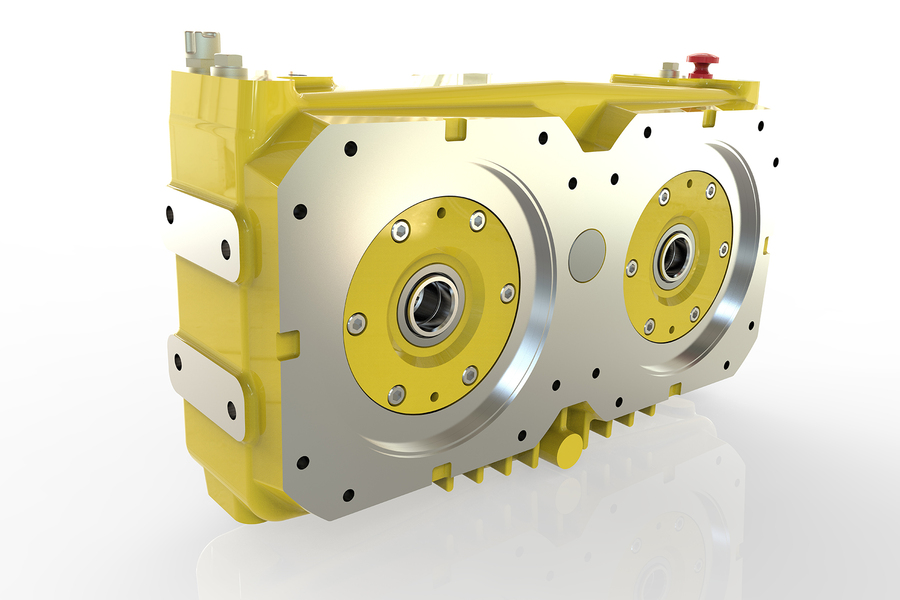

A further development is the compact type 4669 summation gearbox. This unit can be fitted directly to two integrated electric motors. Thanks to the high degree of production tolerance (radial and axial runout) of the power transmitting components, the massive block casing, the manufacture of assemblies and the excellent quality of the gearing, a high degree of operational reliability and smooth running are ensured. Stiebel has developed the summation gearbox primarily as a sustainable tractive force for medium and heavy-duty electric commercial vehicles and mobile working machines. The solution can alternatively be designed to accommodate a generator which is driven via a cardan flange.

Stiebel Drive Technology is also providing highly adaptable support for diverse ideas in the area of mobile hydraulics with its single-stage type 4382 transfer gearbox from the P2000 series. Following the proven modular design principle, this torsionally stiff gearbox offers a range of different mounting variants. Connection is possible via a cardan flange or SAE case. On the take-off side there are three pump connections with freely selectable SAE connectors. With its weight of 200 kg and block casing, this compact gearbox offers space-saving integration possibilities. The lubrication of all relevant components is undertaken by a special system with internal ribbing and oil grooves. Technical facts relating to the pump drive: Maximum torque per drive is 1500 Nm with maximum rotational speed up to 3000 min-1 at a motor power of 530 kW and a transmission ratio of i = 0.6572 to 1.5217.

The type 4395 transfer gearbox with integrated, drive-side clutch offers many different drive options, such as diesel-electric hybrid solutions for instance. The very large shaft spacing of the power take-off shafts in inline configuration (achieved with offset intermediate shafts) allows large motor components up to SAE size 0 to be fitted, both in drive and direct drive mode, and simultaneously hydraulic drives up to SAE size E to be driven by the drive shafts on both sides. The benefits are particularly apparent in terms of the optimized – and therefore environmentally friendly – energy and fuel consumption figures.

A different solution is offered by the type 4611 pump drives which are equipped with two different transmission ratios at the pump take-offs. This facilitates optimum output speeds for various types of hydraulic pump. The Stiebel gearbox is ideally suited for use in snow groomers or utility vehicles.

GrúasRigar relocates construction crane at the Sagrada Familia in Barcelona using Liebherr LTM 1500-8.1 mobile crane

Spanish crane contractor Grúas Rigar demonstrated a very high level of professionalism in November when tackling a difficult crane job at the Sagrada Familia in Barcelona. One of the three massive construction cranes had to be relocated. Rigar used one of its largest telescopic cranes, a Liebherr LTM 1500-8.1, to tackle the job.

Work was started on the construction of the Roman Catholic basilica, Sagrada Familia, in Barcelona in 1882. The church designed by Antoni Gaudi has still not been completed. Current plans are to finish the structure in 2026 to mark the 100th anniversary of Gaudi's death. At that point the Sagrada Familia will be 172.5 m high, in other words more than eleven metres higher than the current highest church tower in the world, Ulm Minster.

Despite the fact that the road was closed, the Rigar team had very little space available to deliver the eight-axle mobile crane and its accessories. Using 165 tonnes of ballast and a 70 metre luffing jib, it dismantled the construction crane and later reassembled it at a different location. The Rigar team impressed everybody on site by the precision and smooth way in which they completed the job.

Grúas Rigar, based in Valencia, is chaired by Mr. José Antonio García Marín. Today the company operates more than 40 cranes in its different offices located along the Mediterranean. The company’s main work includes crane work, heavy haulage, work platforms and the assembly of prefabricated concrete components. Additionally, Rigar has an Engineering Department specialized in studies, consulting and load movement control and is also a collaborating center for the internal training of its clients in the field of safety.

The LTM 1500-8.1 was first unveiled at the Bauma in Munich in 1998. The 500th machine of this type left the plant in Ehingen in March 2015.This makes the LTM 1500-8.1 the most successful large crane of all time.

Ultime notizie di OnSite News

Lifting

20/09/2024

Tele Radio Handhelds for Lifting Applications

Tele Radio has reminded industry of the benefits of two hand...

Logistics

13/09/2024

U17 transported on SCHEUERLE InterCombis to museum destination

The Kübler haulage company team transported the spectacular...

Lifting

12/09/2024

Sinoboom introduces second-generation RT scissor lifts

Four models in Sinoboom’s range of electric and diesel rough...

Lifting

09/09/2024

Tadano CC 68.1250-1 and CC 38.650-1 lift steel bridge sections at the Porto di Prà shipyard

Vernazza Autogru relies on tried-and-true crawler crane duo...

Earthmoving Machinery

06/09/2024

Rokbak relationship enhances FT Aggregates' service quality

FT Aggregates is on a mission to produce the highest quality...

Lifting

05/09/2024

New Tadano AC 3.045-1 city crane for switzerland-based Richi AG

The new crane was handed over by Tadano Sales Manager Michae...

Altri International

International

26/09/2024

Rock Crusher WRC 240i speeds up recycling project for new Trailer Port in Dresden

Particularly cost-efficient in-situ processing of coarse mat...

International

24/09/2024

Kramer presents the new compact 5045 wheel loader

Kramer presents the new compact 5045 wheel loader, adding an...

International

23/09/2024

Wirtgen Group will be presenting its range at Asphaltica

The Wirtgen Group will be presenting its entire range of pro...

International

20/09/2024

SOFIALEX completes fast-track build with Potain Igo T 130 cranes

SOFIALEX finished a four-month prefabricated construction pr...

International

20/09/2024

Tele Radio Handhelds for Lifting Applications

Tele Radio has reminded industry of the benefits of two hand...

International

19/09/2024

Volvo CE inaugurates new facilities to support production of electric wheel loaders in Arvika

The industry shift has taken another exciting leap forward a...