Home \ International \ Stirnimann debuts three Potain Hup C 40-30 cranes on Swiss railway project

Stirnimann debuts three Potain Hup C 40-30 cranes on Swiss railway project

18/05/2020

Pubblicato da Redazione

The project is the first that the innovative crawler mounted Hup C 40-30 self-erecting cranes have been used on.

The first Potain Hup C 40-30 crawler mounted self-erecting cranes have been deployed on a job site in Switzerland.

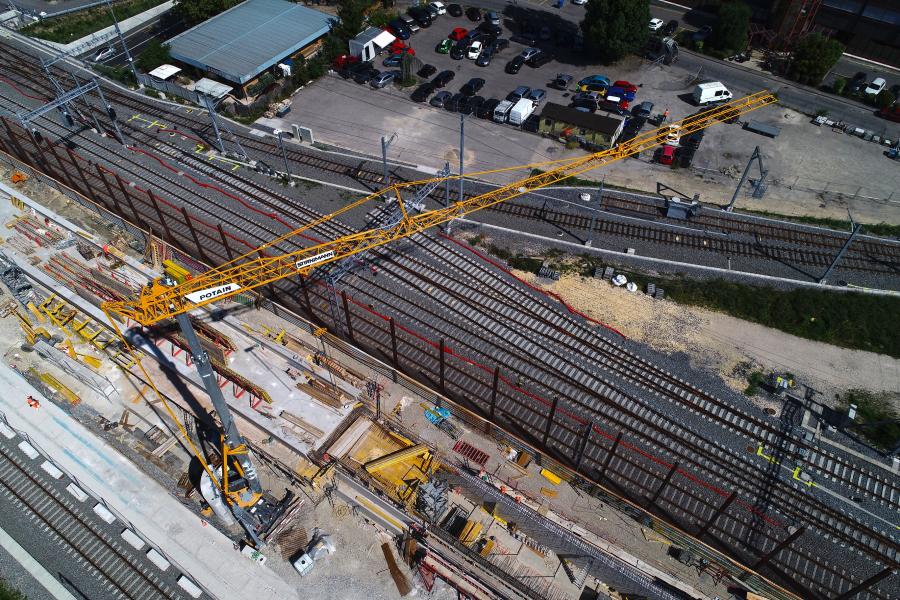

Construction equipment supplier and longstanding customer Stirnimann AG has supplied three cranes to contractor Implenia for the construction of a 1.2 km rail flyover at Renens VD station, close to Lausanne.

The flyover will allow trains to pass over existing railway tracks, helping to improve efficiency and convenience for passengers. The cranes are working around the clock, as the flyover is planned for completion in December 2021.

The Hup C 40-30 was launched at bauma 2019 and is unique to Potain’s self-erecting tower crane line, as it is the first crane to be enhanced with crawler tracks for ultimate mobility on job sites with challenging terrain. The crane was developed side-by-side with Stirnimann AG as part of Manitowoc’s Voice of the Customer program. Stirnimann, based in Olten, Switzerland, was the Hup C 40-30’s first buyer, purchasing six of the unique crawler self-erecting cranes. Half of these cranes are now being used on the Renens VD project.

The Hup C 40-30 impressed contractor Implenia with its ease-of-transportation, fast and simple erection, and versatility and mobility on the job site. The special application crane boasts a compact transport length of 13.5 m and a width of 2.55 m. With its embedded power generator, it can also travel and erect by itself. When folded, the crane can travel at 25 m/min and features front levelling up to 30 percent and side levelling up to 12 percent.

During the erection process, the crane is hydraulically leveled and has a footprint of 5 m x 4.5 m. Once erected, the crane exhibits up to 5 percent front and side levelling. It can also be repositioned while fully erected and travels at a speed of 10 m/min. This is a big advantage as the cranes have to be repositioned alongside the bridge every two weeks.

“The self-erecting Potain Hup C 40-30 is a truly innovative concept — it’s the first crane to be enhanced with crawler tracks for ultimate mobility,” said Fritz Oschwald, managing director of Stirnimann. “To build the rail flyover in Renens, Implenia has rented three Hup C 40-30 cranes for ten months. The feedback we have received so far is very positive. Thanks to the mobility of the crane on the job site, our client is able to get to work efficiently and make good progress.”

Ultime notizie di Manitowoc Cranes Group Italy

Lifting

25/11/2024

New Grove GMK3060L-1 drives busy schedule for Mann Crane Hire

• Mann Crane Hire selected the GMK3060L-1 for its class-lead...

Lifting

06/11/2024

Dutch crane company receives one of Europe’s first Grove GMK4080L all-terrain cranes

Kraanverhuur Tholen has purchased a new Grove GMK4080L all-t...

Lifting

30/10/2024

Eight Potain cranes team up to construct Milan’s stunning new CityWave building

• CMB and Colombo Costruzioni – two of the most respected na...

Lifting

28/10/2024

Grove upgrades the GMK6400-1 to GMK6450-1

Grove responded to customer demand for a higher-capacity cra...

Lifting

18/10/2024

Manitowoc to launch major new product at bauma China 2024

• Manitowoc will announce a significant new crane introducti...

Lifting

07/10/2024

Manitowoc introduces new Potain Igo M self-erecting crane

The Potain Igo M 24-19 is a ideal choice for new home constr...

Altri International

International

26/11/2024

Mota-Engil orders 10 Liebherr railroad excavators for a major project in West Africa

The Portuguese construction company Mota-Engil has once agai...

International

25/11/2024

New Grove GMK3060L-1 drives busy schedule for Mann Crane Hire

• Mann Crane Hire selected the GMK3060L-1 for its class-lead...

International

25/11/2024

Prinoth Unveils Expanded Production Facility in Granby, Canada

Prinoth held an event to announce the official opening of it...

International

23/11/2024

GPMat International takes delivery of two Raimondi T147s residential development in the South of France

- Official agent of France expands its product lineup with t...

International

22/11/2024

Sarens acquires additional SCHEUERLE SPMT K24 modules

renowned for its expertise in crane rental services, heavy l...

International

22/11/2024

Five WOLFF cranes modernize Oslo’s Ulven district

With a total of five WOLFF cranes of type 7534.16 Clear, Wol...