Home \ International \ The Dynapac spray paver SD2500CS PROTAC

The Dynapac spray paver SD2500CS PROTAC

13/04/2023

Pubblicato da Redazione

Dynapac recently launched the SD2500CS PROTAC spray paver, developed in collaboration with Secmair – a sister company of Dynapac in the Fayat Group.

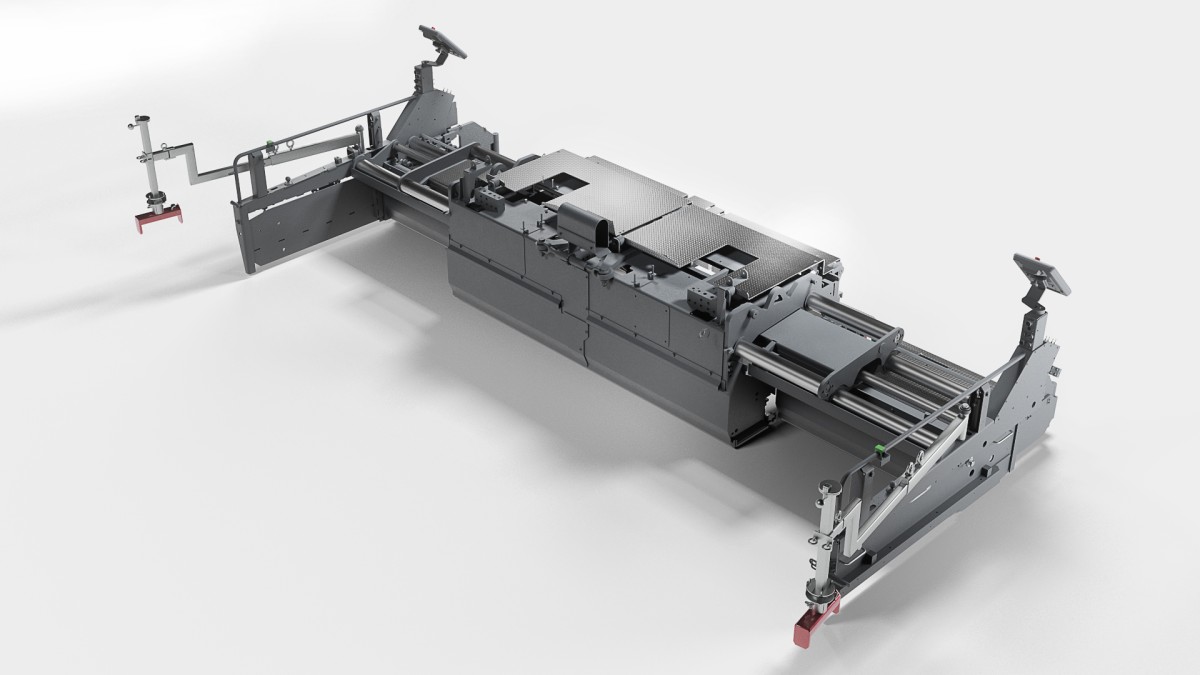

Dynapac recently launched a spray paver on the market: the new machine, which can be experienced at the 2022 Bauma, has been developed in collaboration with Secmair – a sister company of Dynapac in the Fayat Group, as well as in collaboration with numerous customers. Development was boosted by the fact that the know-how and expertise from specialists in road repair, road construction experts, and customer requirements flowed into its creation. The new Dynapac spray paver offers a variety of new functions for even more precise results, safety, and hassle-free operation. To ensure the longevity of road surfaces, an optimal composite layer of the asphalt layers is essential. The SD2500CS PROTAC spray paver successfully applies the emulsion (pressure-sensitive adhesive) and asphalt paving in a single operation.

The SD2500CS PROTAC spray paver is primarily designed for two application areas. The first is for the application of thin asphalt surface layers using “Thin layer in hot paving on sealant”. The second is for road repair, as well as for new road construction and everyday asphalting tasks. The use of thin asphalt surface layers, especially for maintenance construction, is ideal for weathered, but intact substrates. Thanks to the sealing via a binder film, it provides a permanent protection layer against moisture as well as offering more grip. The result: roads with significantly longer service lives. The SD2500CS PROTAC sprays emulsion and applies asphalt in a single operation. In doing so, it increases operational efficiency while saving resources. What’s more, the road can also be opened faster traffic, thus reducing construction costs. Additionally, numerous measurements have confirmed that DSH-V surfaces have a noise reduction potential of about 5 dB(A). Moreover, the low thickness layer helps conserves resources, material use, time, and energy. The second application is found in the construction of new roads, because, here as well, the formation of an intensive layer guarantees a long service life. The excellent grip properties, flatness, and durability come together in just a 1.5-2 cm thick layer when applied by the spray paver. And the low layer thickness saves resources - material usage, time and energy.

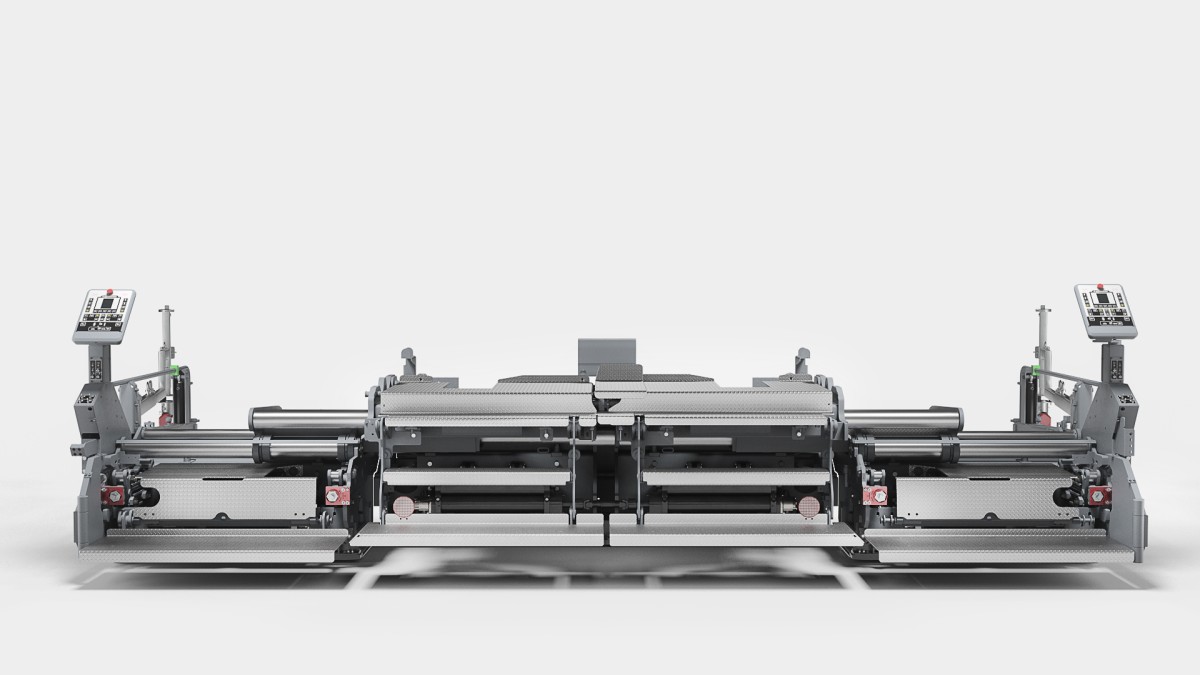

The latest member of the Dynapac paver family incorporates two important functions in one machine: application and spraying. In contrast to similar machines, where the spray function is placed "on the paver", the Dynapac spray paver uses technology that seamlessly integrates the spray feature into the machine. The spray unit is easily activated and controlled via a robust and user-friendly touch display directly on the control panel. This allows the operator to effortlessly monitor and adjust the spray system. Access to the spray nozzles is quick and hassle-free and each nozzle can be opened and closed individually with the touch of a finger. Another practical feature is that the spray bars automatically follow the screed movement, thus ensuring optimum uniformity and control. If necessary, the screed operator can retract or extend the spray bars regardless of the screed position, so that objects can be omitted or included from the emulsion.

The maximum spray width is 6.5 m which is wider than other conventional offers. The 25 independent nozzles are automatically activated by moving the spray bar or extending the screed. The Dynapac spray paver can hold up to 2100 liters of emulsion and is equipped with a filling neck and level display on each side This optimally supports the filling process and is particularly convenient for the operator. The combination of heating mats and a powerful heating rod with a total heating capacity of 18 kW ensure gentle, yet rapid heating. Thanks to the heating mats, separation of the emulsion is prevented and even smaller amounts of 100l in the tank can be warmed up. Both the heating rods and the heating mats are controlled automatically, meaning that both the screed and emulsion are brought up to temperature in an efficient way.

The paver offers operators an excellent all-around view for even more crew safety and comfort on the construction site. A crucial part of this development was the testing of different nozzles, settings, and software programming to find an optimal spray pattern that combined a low fog generation with a comprehensive and precise spray pattern. In achieving this, authorities, construction companies, crews, and the environment benefit.

The well-balanced spray paver has a basic width of 2.55 m which ensures quick and easy transport. The SD2500CS PROTAC can also be loaded with emulsion residues in the tank. Cleaning is uncomplicated thanks to an automatic cleaning system that is activated at the push of a button. The operator can choose between different cleaning modes to adapt the system to the needs and demands of the jobsite.

Customer Veidekke, one of the largest construction companies in Scandinavia, recently worked with the SD2500 CS PROTAC on a night job site in Norway near Oslo. The crew was very happy with the machine and had no problems to operate the spray paver for the first time during a nighttime operation due to the intuitive user interface, reports Atle Sjoen, supervisor at Veidekke. They had a few minor comments about the operation of the touchscreen, which Dynapac has already taken into account during development. The spray pattern was seamless, even with low quantities of 200g/m² and the mat was - as you can see in the pictures - very even and therefore the job was successfully done. Sjoen added: "Working with the spray paver was not so different from working with a paver without spray function. Due to the great visibility for the driver, we felt absolutely safe on the job.”

Ultime notizie di OnSite News

Earthmoving Machinery

25/11/2024

Prinoth Unveils Expanded Production Facility in Granby, Canada

Prinoth held an event to announce the official opening of it...

Logistics

22/11/2024

Sarens acquires additional SCHEUERLE SPMT K24 modules

renowned for its expertise in crane rental services, heavy l...

Equipments

21/11/2024

SITECH partners with Royal Engineers to create poppy and demonstrate tech offering

The demostration involved creating a ground-level poppy desi...

Earthmoving Machinery

20/11/2024

Strong and stable RA30 trucks carry the weight at New Caledonian mine

Three Rokbak RA30 trucks are delivering exceptional durabili...

Lifting

20/11/2024

Tadano AC 7.450-1 Performs Double Duty in Wisconsin

A cost-saving and versatile solution was already on site - a...

Lifting

11/11/2024

Tadano AC 7.450-1 all terrain crane for the Victoria Tower in Mannheim

Tadano AC 7.450-1 all terrain crane lifts cooling unit to to...

Altri International

International

28/11/2024

Hitachi's Zaxis-7 excavator is a favourite for Norwegian family-business

Norwegian family business JO Moen AS has added a ZX225USRLC-...

International

27/11/2024

Home of Volvo Construction Equipment’s pioneering articulated haulers advances to Climate Efficient Site

As one of the construction industry’s most active drivers of...

International

26/11/2024

Mota-Engil orders 10 Liebherr railroad excavators for a major project in West Africa

The Portuguese construction company Mota-Engil has once agai...

International

25/11/2024

New Grove GMK3060L-1 drives busy schedule for Mann Crane Hire

• Mann Crane Hire selected the GMK3060L-1 for its class-lead...

International

25/11/2024

Prinoth Unveils Expanded Production Facility in Granby, Canada

Prinoth held an event to announce the official opening of it...

International

23/11/2024

GPMat International takes delivery of two Raimondi T147s residential development in the South of France

- Official agent of France expands its product lineup with t...