Home \ International \ The Wacker Neuson Group opens its new logistics center

The Wacker Neuson Group opens its new logistics center

25/06/2024

Pubblicato da Redazione

The Wacker Neuson Group opens its new logistics center and strengthens its global supply of spare parts.

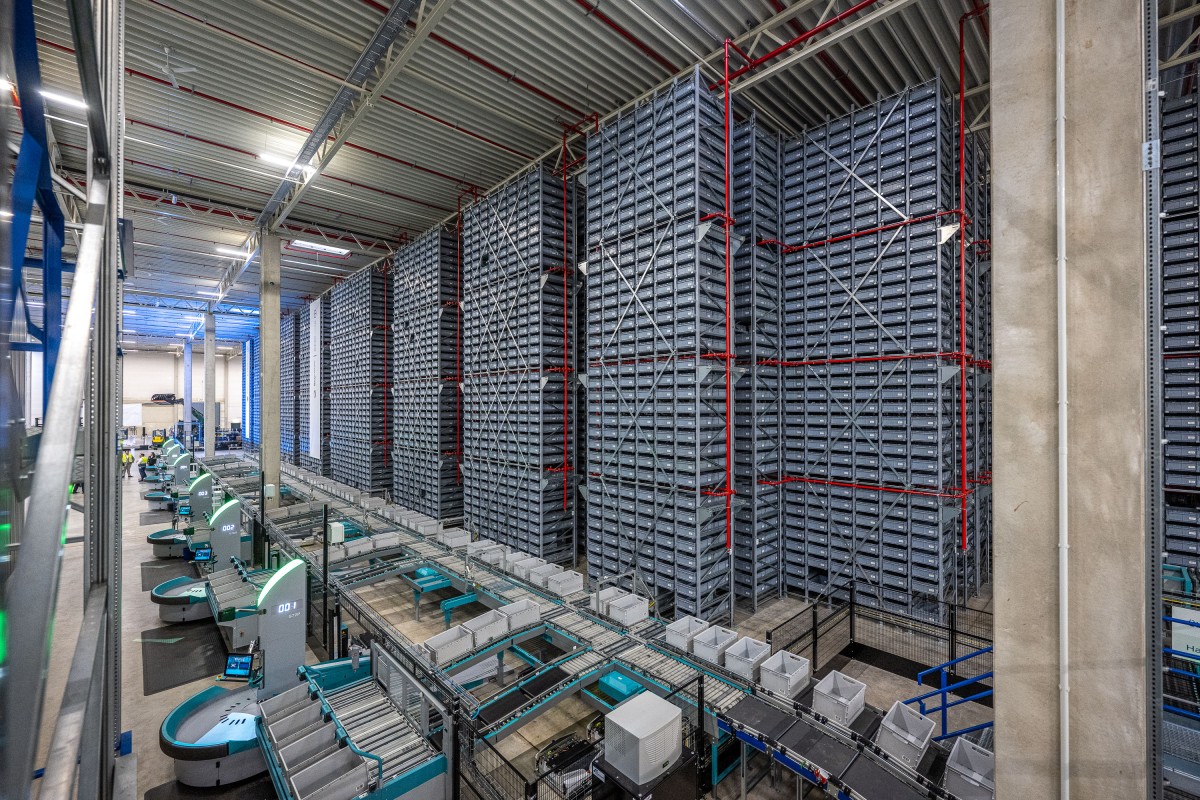

At the start of June 2024, the Wacker Neuson Group put its new spare parts logistics center in Mülheim-Kärlich, Germany into operation after 1.5 years of construction. The state-of-the-art logistics site is strategically positioned between the Frankfurt am Main and Cologne/Bonn airports. It is therefore ideally located for connection to the international transport networks. In an area of 55,000 square meters, around 100,000 different spare parts for construction equipment and compact machines are stored. The warehouse in Mülheim-Kärlich will be the hub for the global spare parts distribution for the three core brands of the company: Wacker Neuson, Kramer, and Weidemann.

With its future-proof storage capacity, the new distribution center will secure the basis for further expansion of the Wacker Neuson Group's spare parts and services business and thus support the company's long-term growth strategy. “The opening of our parts distribution center in Mülheim-Kärlich is a decisive step towards becoming a long-term solution provider for our customers. Not only will spare parts be stored here, but additional services will also be offered to optimize and further develop customer support,” explains Andrew Voigt, Managing Director of Wacker Neuson Aftermarket & Services GmbH. “We are the partner on our customers' side for the entire lifetime of the machines and create sustainable relationships – beyond the sale of the machines and construction equipment.”

Warehouse operations are highly efficient with a strong degree of automation and digitalization. This includes an automated small parts warehouse with over 30 robots and around 200,000 storage locations as well as a digital training platform and innovative shop-floor management. "Thanks to the central location and state-of-the-art warehouse technology, customers benefit from a significantly improved service, more flexibility in ordering times and an optimized transport network," explains Steffen Streubel, Head of Parts Operations at Wacker Neuson Aftermarket & Services GmbH. With the construction and operation of the new distribution center, the Wacker Neuson Group is also taking care to keep its own CO2 footprint as low as possible. The building was constructed in accordance with the highest sustainability standards of the German Sustainable Building Council (DGNB) and has applied for the corresponding platinum certification. It is equipped with a photovoltaic system with a peak output of 3.2 megawatts and energy-efficient storage technology. E-charging stations for employees and visitors are also planned.

The logistics experts of Kühne+Nagel will assume the operational business on-site. As a long-term partner of the Wacker Neuson Group, the successful collaboration is being continued and developed. With the development of the global spare parts supply the Wacker Neuson Group is underlining its strategic goals and strengthening customer support for its construction and agriculture partners.

Picture of the opening, persons f.l.t.r.: Christoph Holzberger, Contract Logistics Site Manager, Kühne+Nagel (AG & Co.) KG; Axel Krichel, Mitglied der Geschäftsleitung, Kühne+Nagel (AG & Co.) KG; Gianfranco Sgro, Executive Vice President Contract Logistics Management Board, Kühne+Nagel (AG & Co.) KG; Alexander Greschner, Chief Sales Officer, Wacker Neuson Group; Andrew Voigt, Managing Director Corporate Aftermarket, Wacker Neuson Aftermarket & Services GmbH; Steffen Streubel, Head of Parts Operations, Wacker Neuson Aftermarket & Services GmbH.

Ultime notizie di Wacker Neuson Italia

Earthmoving Machinery

13/05/2024

Wacker Neuson Group: first quarter of 2024 weaker than 2023

Group revenue down 11.1 percent year-over-year to EUR 593.1...

Earthmoving Machinery

05/04/2024

Wacker Neuson Group: strong revenue and earnings growth in fiscal 2023

The Wacker Neuson Group again enjoyed strong growth in fisca...

Earthmoving Machinery

27/03/2024

Wacker Neuson Group focuses on digital solutions and IoT expertise

the Wacker Neuson Group has expanded its digital strategy to...

Earthmoving Machinery

09/11/2023

Wacker Neuson Group posts double-digit percentage growth in first nine months despite economic slowdown

Group revenue up 22.7 percent in the first nine months to EU...

Earthmoving Machinery

31/08/2023

Wacker Neuson Group remains on growth track in first half of 2023

Group revenue up 27.4 percent in first half of the year to E...

Equipments

29/05/2023

Wacker Neuson Group strengthens attachments business

The new line of business will be anchored in the Corporate A...

Altri International

International

21/11/2024

Kleemann: New compact crusher used for recycling

Impact crusher MOBIREX MR 100i NEO impresses during operatio...

International

21/11/2024

SITECH partners with Royal Engineers to create poppy and demonstrate tech offering

The demostration involved creating a ground-level poppy desi...

International

20/11/2024

Strong and stable RA30 trucks carry the weight at New Caledonian mine

Three Rokbak RA30 trucks are delivering exceptional durabili...

International

20/11/2024

Tadano AC 7.450-1 Performs Double Duty in Wisconsin

A cost-saving and versatile solution was already on site - a...

International

19/11/2024

Liebherr Tower Cranes and John Paul Construction celebrate 50 years of partnership

Irish construction company John Paul Construction is celebra...

International

18/11/2024

The CMC i23 aerial platform: an example of high performances

CMC i23 is designed to maximise operational efficiency in al...