Home \ International \ Trevi Construction Co. Ltd. at the Hong Kong's International Airport

Trevi Construction Co. Ltd. at the Hong Kong's International Airport

21/07/2022

Pubblicato da Ettore Zanatta

Trevi Construction Co. Ltd. is working on the important project of the Hong Kong International Airport Three Runway System Project.

Trevi Construction Co. Ltd., company part of Trevi Group, a world leader in the field of underground engineering from A to Z (special foundations, soil consolidation, recovery of polluted sites), in the design and marketing of specialized technologies in the sector, have participated and is working on the important project of the Hong Kong International Airport Three Runway System Project.

TCHK is doing deeper ground consolidations works, with Jet Grouting technology for the Main reclamation works in some of the areas of the HKIA project. The Airport Authority Hong Kong (AA) is a statutory body wholly owned by the Hong Kong SAR Government. Established in 1995, the AA is responsible for the operation and development of Hong Kong International Airport (HKIA). In this project TREVI Construction Co. Ltd has been work with different Main Contractor/Contracts: ZHEC-CCCC-CDC Joint Venture (Main Reclamation Works); Gammon (APM and BHS Tunnels and Related Works); China State Construction Engineering (Hong Kong) Ltd (North Runway Modification Works).

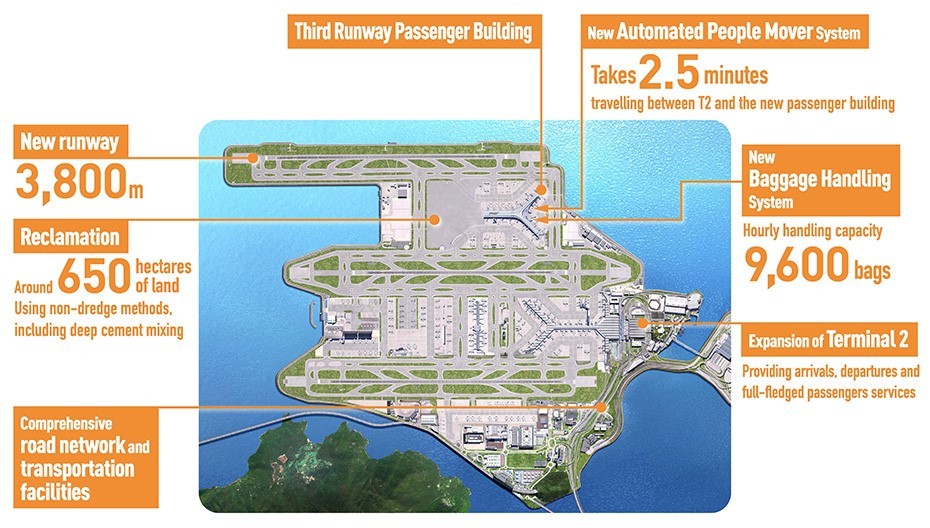

To strengthen Hong Kong’s status as an international aviation hub, and to cater for the city’s long-term air traffic demand, Hong Kong International Airport is developing into a three-runway system.The scale of the three-runway system (3RS) project is almost equal to building a new airport next to the existing one. It involves the following seven core projects:

• Reclaiming approximately 650 hectares of land north of the existing airport island (equivalent to 34 Victoria Parks, or 100 artificial islands for the New Wing of the Hong Kong Convention and Exhibition Centre), using non-dredge methods including deep cement mixing: building the Third Runway Passenger Building and an associated apron; building a new, 3,800-metre-long runway and its supporting taxiway systems. The existing North Runway will also be reconfigured; expanding Terminal 2 to provide full-fledged passenger services including arrivals and departures facilities; building a new, 2,600-metre-long Automated People Mover (APM) system that will connect Terminal 2 with the new passenger building. The new APM system will operate at a top speed of 80km/h and transport up to 10,800 passengers per hour; building a new Baggage Handling System (BHS) linking Terminal 2 with the new passenger building. The new BHS will be capable of handling 9,600 bags per hour; building other associated airport support infrastructure, road network and transportation facilities.

ZHEC-CCCC-CDC Joint Venture is the contractor appointed to undertake the main reclamation works. Reclaiming approximately 650 hectares of land north of the existing airport island (equivalent to 34 Victoria Parks, or 100 artificial islands for the New Wing of the Hong Kong Convention and Exhibition Centre), using non-dredge methods including Deep Cement Mixing (DCM). One of the DCM technologies used in this project is the: Jet Grouting, improves soil mechanical and permeability properties by using high-speed Jets of water/cement mixtures injection treatment. Jet Grouting can be advantageously in the following conditions: difficult logistic conditions, confined spaces, presence of obstacles to cross, high-depth treatment with crossing of voids. The Jet Grouting technique allows to improve a wide range of soil types. As it is based on soil erosion, soil erodibility is crucial to the result. The more consistent the soil to be treated, the smaller the column diameter. Therefore, larger columns can be obtained in loose soft soils and smaller ones in cohesive soils. Depending on the number of fluids used, there are three main techniques: Monofluid (Trevi T1), a water/cement mixture is injected to break up and simultaneously mix the soil in-situ; diameters usually range from 0.4 to 1m; Bifluid (Trevi T1/S), a combination of water/cement mix and air is injected to break up and simultaneously mix the soil in-situ; diameters usually range from 0.8 to 2.5m; Triple fluid (Trevi T2), a combined water/air jet is used to break up and partially remove the soil in-situ, whereas soil mixing is ensured by a lower water/cement injection.

In this large project TCHK has awarded the majority part of the Jet Grouting works. TCHK team started the Jet Grouting works in this project in October 2019 and works are still in progress. So far TCHK team has consolidated and grouted about 311,000m3 of soil, in 6,900nos. columns of different diameters, from 1,200 to 2,500mm, majority are 2,500mm diameters columns, for a total length of 73,000m of soil grouted. There was a production peak period where TCHK worked with 11nos. JG teams in different areas/contracts. There were about 100nos. workers engaged in these projects at the same time. The main equipment at site were 11nos. Soilmec microdrilling rigs SM14 and SM20, 11 High Pressure Pump, 11 Backhoe excavator, 11 Atlas Air Compressor, 6 Agitator, 2 Grout mixer, 4 Cement Silos, 2 Pemo Pump and a 40ton Crane Lorry.

Ultime notizie di OnSite News

Earthmoving Machinery

25/11/2024

Prinoth Unveils Expanded Production Facility in Granby, Canada

Prinoth held an event to announce the official opening of it...

Logistics

22/11/2024

Sarens acquires additional SCHEUERLE SPMT K24 modules

renowned for its expertise in crane rental services, heavy l...

Equipments

21/11/2024

SITECH partners with Royal Engineers to create poppy and demonstrate tech offering

The demostration involved creating a ground-level poppy desi...

Earthmoving Machinery

20/11/2024

Strong and stable RA30 trucks carry the weight at New Caledonian mine

Three Rokbak RA30 trucks are delivering exceptional durabili...

Lifting

20/11/2024

Tadano AC 7.450-1 Performs Double Duty in Wisconsin

A cost-saving and versatile solution was already on site - a...

Lifting

11/11/2024

Tadano AC 7.450-1 all terrain crane for the Victoria Tower in Mannheim

Tadano AC 7.450-1 all terrain crane lifts cooling unit to to...

Altri International

International

27/11/2024

Home of Volvo Construction Equipment’s pioneering articulated haulers advances to Climate Efficient Site

As one of the construction industry’s most active drivers of...

International

26/11/2024

Mota-Engil orders 10 Liebherr railroad excavators for a major project in West Africa

The Portuguese construction company Mota-Engil has once agai...

International

25/11/2024

New Grove GMK3060L-1 drives busy schedule for Mann Crane Hire

• Mann Crane Hire selected the GMK3060L-1 for its class-lead...

International

25/11/2024

Prinoth Unveils Expanded Production Facility in Granby, Canada

Prinoth held an event to announce the official opening of it...

International

23/11/2024

GPMat International takes delivery of two Raimondi T147s residential development in the South of France

- Official agent of France expands its product lineup with t...

International

22/11/2024

Sarens acquires additional SCHEUERLE SPMT K24 modules

renowned for its expertise in crane rental services, heavy l...