Home \ International \ Ugol Rossii & Mining 2018: Flexco facilitates maintenance work in underground mining

Ugol Rossii & Mining 2018: Flexco facilitates maintenance work in underground mining

08/05/2018

Pubblicato da Redazione

Ugol Rossii & Mining 2018: Flexco facilitates maintenance work in underground mining

The conditions in underground mining can be extreme for man and machine. The Flexco GmbH offers solutions that enable conveyor belt operators to improve their processes and considerably simplify maintenance and repair work in this harsh environment. At the Ugol Rossii & Mining trade fair, which will take place from 5 to 8 June in Novokuznetsk, Russia, the specialist company will also be showing the Flexco XP belt fasteners.

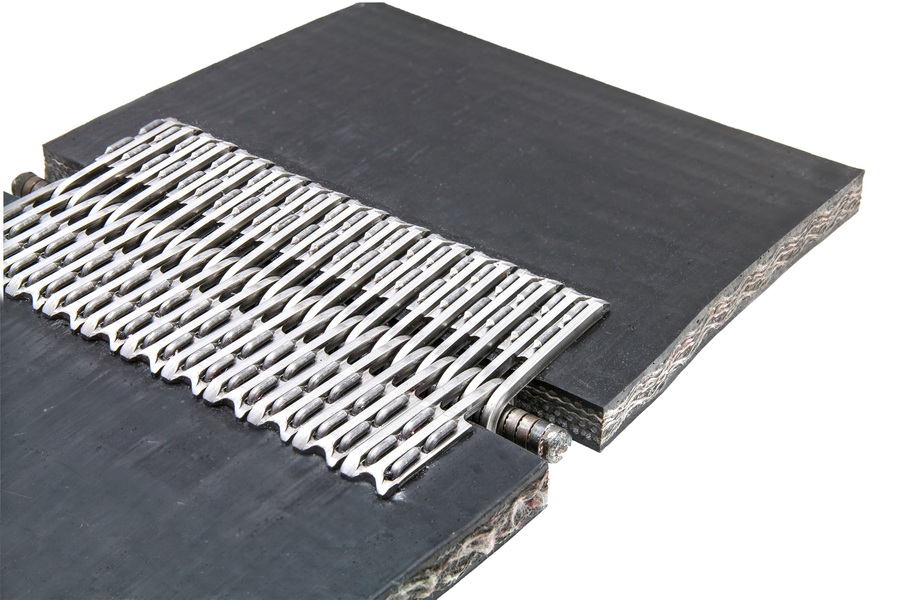

The mechanical belt fasteners of the Flexco XP series have been specially developed for use in mining and underground operations. They are suitable for conveyor belts made of woven PVG/PVC up to a strength of 1,750 N/mm. Users can apply the fasteners with a hydraulic press, or manually without damaging the fibres. The flat design of the fasteners improves the approach for cleaning systems and reduces contact with side sealing profiles and return rollers. The system therefore wears more slowly, and the splices hold for considerably longer than those of comparative competitor systems. This enables mine operators to increase the productivity of their conveyor systems, as they have fewer breakdowns and less maintenance work.

When a conveyor belt is stopped for maintenance, its own weight can create problems by distributing the tension unevenly. To ensure that a belt can be safely cut and securely spliced by service technicians, the forces in the area under repair should be spread over the whole width – and this is exactly why Flexco developed the TUG HD belt clamp. It is suitable for a variety of materials and belt types – and it also meets rigorous industry safety standards. TUG HD belt clamps are used to restrain or pull a conveyor belt and then hold it firmly in place.

To carry out maintenance work ergonomically, Flexco will be showing an efficient lifting device at the trade fair – the Flexlifter. The Flexlifter enables service personnel to hoist the tensioned belt on the system to the required height without physical exertion. The belt lifter can be loaded with up to three tonnes and is available in three sizes. And because of its particularly lightweight construction, the technician can move it about with ease.

At the Ugol Rossii & Mining trade fair, Flexco will also be providing information on its extensive range of scrapers – because where bulk material is conveyed, carryback is formed. For the operators of conveyor belt systems, this is a cost factor which is not to be underestimated. Scrapers free the belt of the adhering material. The components consist of a plastic or hard metal blade and a spring tensioning system that ensures optimum contact of the blade with the conveyor belt.

Ultime notizie di OnSite News

Logistics

22/11/2024

Sarens acquires additional SCHEUERLE SPMT K24 modules

renowned for its expertise in crane rental services, heavy l...

Equipments

21/11/2024

SITECH partners with Royal Engineers to create poppy and demonstrate tech offering

The demostration involved creating a ground-level poppy desi...

Earthmoving Machinery

20/11/2024

Strong and stable RA30 trucks carry the weight at New Caledonian mine

Three Rokbak RA30 trucks are delivering exceptional durabili...

Lifting

20/11/2024

Tadano AC 7.450-1 Performs Double Duty in Wisconsin

A cost-saving and versatile solution was already on site - a...

Lifting

11/11/2024

Tadano AC 7.450-1 all terrain crane for the Victoria Tower in Mannheim

Tadano AC 7.450-1 all terrain crane lifts cooling unit to to...

Earthmoving Machinery

08/11/2024

Terapro Construction and Rokbak announce distribution agreement

Terapro Construction will now supply Rokbak articulated haul...

Altri International

International

23/11/2024

GPMat International takes delivery of two Raimondi T147s residential development in the South of France

- Official agent of France expands its product lineup with t...

International

22/11/2024

Sarens acquires additional SCHEUERLE SPMT K24 modules

renowned for its expertise in crane rental services, heavy l...

International

22/11/2024

Five WOLFF cranes modernize Oslo’s Ulven district

With a total of five WOLFF cranes of type 7534.16 Clear, Wol...

International

21/11/2024

Kleemann: New compact crusher used for recycling

Impact crusher MOBIREX MR 100i NEO impresses during operatio...

International

21/11/2024

SITECH partners with Royal Engineers to create poppy and demonstrate tech offering

The demostration involved creating a ground-level poppy desi...

International

20/11/2024

Strong and stable RA30 trucks carry the weight at New Caledonian mine

Three Rokbak RA30 trucks are delivering exceptional durabili...