Home \ International \ Vögele: Safe and healthier asphalt paving

Vögele: Safe and healthier asphalt paving

28/08/2024

Pubblicato da Ettore Zanatta

Dash 5 road pavers from Vögele increase user-safety and reduce exposure to harmful emissions.

Around the world, increasingly stringent guidelines are setting a tighter focus on accident prevention and health protection in road construction. In view of this, Vögele has aligned the concept of its Dash 5 generation pavers even more strongly towards ensuring the health and safety of their users. This includes new functions such as setting up and starting the machine from the ground, an integrated lighting system and a revised ventilation system.

In recent years, risk-awareness and safety standards in the asphalt paving sector have become increasingly important around the world – and, as a result, demands with regard to road pavers. Depending on the country, construction contractors must ensure compliance with a whole range of different regulations and workplace threshold values. Paver specialist Vögele therefore prioritises the protection of the machine operator in all of its development processes. ‘A road paver is not just a machine that must function at the highest technological level, but is also, and above all, a workplace’, says Bastian Fleischer, Product Manager at Vögele. ‘Only when operators can work safely and ergonomically with a paver that simultaneously protects their health, is it possible to guarantee efficient, high-quality paving. Good working conditions reduce the risk of health issues and accidents. Regardless of any country-specific regulations, user-safety therefore always has utmost priority in all of our developments – and especially in the case of the Dash 5 generation machines.’

Vögele has developed the automated Paver Access Control (PAC) function to make the preparation for paving safer. The control unit positioned on the screed enables users to start all the initial steps - such as switching on the lights, starting the diesel engine, booting the machine control system, raising and locking the weather canopy in place and lowering the screed – to be performed safely and conveniently from the ground at the push of a button. After work, the paver can be returned to the transport position in the same way. This makes setting up and shutting down the paver and loading it onto a low-loader trailer for transportation easier and more convenient. In the dark, the operator switches on the lights to ensure optimum vision before getting onto the paver. Functions such as the automatic locking of the weather canopy make sure that the operator can’t overlook important steps when setting up the machine. ‘PAC avoids errors due to carelessness or negligence, and the clear sequence of the initial steps guarantees absolute reliability’, says Fleischer.

When working at night, in poor visibility or in tunnels, sufficient lighting on and around the road paver is a further safety factor. This is why Vögele has further improved the lighting concept of the Dash 5 generation pavers: An integrated LED lighting system illuminates the paver operator’s platform and all service points accessible from it even more effectively. The lighting of the tow point rams and the freely-positionable floodlights guarantee an ideal overview of all relevant areas. Instead of the light balloons, the new models can also be fitted with additional LED floodlights in fixed mounts on the canopy extension. These evenly illuminate the entire working area up to four metres behind the screed and across a paving width of up to ten metres. After the end of the work, a timer function automatically switches off the lights after giving the operator sufficient time to safely leave the construction site. ‘As the powerful LED lamps illuminate precisely the areas required for setting up and starting the paver, paving or service cases, the new lighting concept effectively reduces the risk of accidents and operating errors’, says Fleischer. ‘What’s more, the paving crew doesn’t need to bring in and install any extra lighting equipment on the construction site. This minimises the risk of accidents and saves time by eliminating set-up times and idle times.’

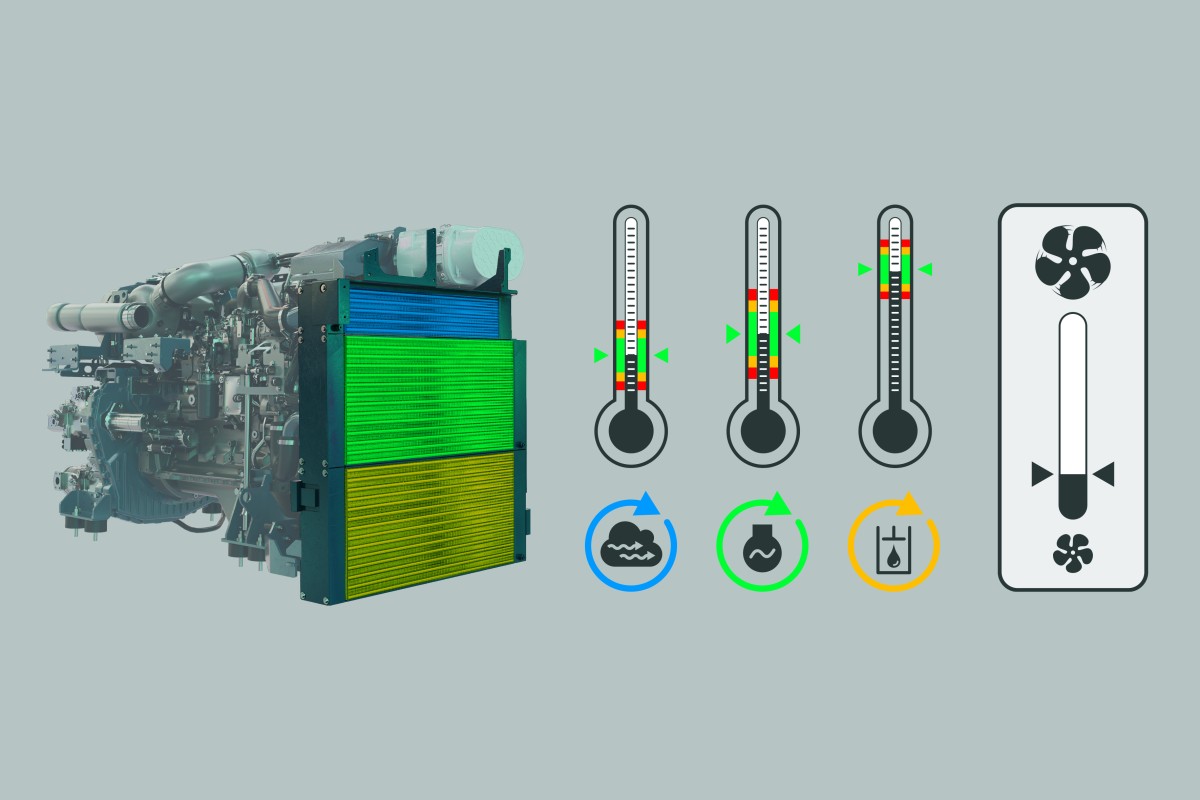

At the same time, the Dash 5-road pavers offer their users more effective health protection and improve the sustainability profile of the road construction contractors. This is due to Vögele’s successes in the further reduction of both noise and CO₂ emissions while maintaining the same engine power output. The reason for this is the combination of revised drive system technology and the improved EcoPlus low-emissions package. As was the case in the previous generation, a variety of technical features contribute to lower fuel consumption and emissions. In the case of the Dash 5 generation, Vögele has optimised the function of the speed-controlled cooling fan to enable more precise calculation of the cooling fan speed and increase it as minimally as necessary for ensuring safe operation of the machine. This leads to lower noise and CO₂ emissions and significantly reduces fuel consumption.

Vögele is continually improving the ventilation system of its road pavers to ensure that operators are more effectively protected against harmful aerosols during asphalt paving. ‘We have been offering a NIOSH-certified ventilation system for our machines for many years’, says Steffen Fickeisen, Head of Special Machines at Vögele. ‘In the Dash 5 generation, we have significantly increased the extraction performance and have also optimised the exhaust air outlet. Its integration in the canopy of the paver instead of at the rear of the operator’s platform significantly reduces the exposure of the operator to harmful aerosols.’ Further improvements are in the pipeline. ‘This is not only a standard feature of our latest machines, we also offer a retrofit package that enables users to have it installed on Dash 3 models’, says Fickeisen.

Apart from the technical solutions for lower exposure to emissions, better lighting, and new automated functions, Vögele also assures the health and safety of users with better ergonomics and the improved design and features of the operator’s workspace. With the revised and upgraded ErgoPlus 5 operating concept, new comfort functions, pivot-mounted operator’s seats, two-stage seat heating, insulated sun blinds, luggage nets and cup holders, the Dash 5 road pavers are consistently geared towards the needs of users. Plug-in tool holders, new transportation solutions such as Logistics Plus, as well as attachment and positioning aids, provide a tidy and logically laid-out workplace and simultaneously ensure safe transportation and fewer set-up errors. ‘With the new road pavers, our goal is the fulfilment of all prerequisites for ideal working conditions and, by doing so, to increase the quality of paving projects and the productivity of road construction contractors’, says Fleischer.

Ultime notizie di Wirtgen Macchine

Earthmoving Machinery

21/11/2024

Kleemann: New compact crusher used for recycling

Impact crusher MOBIREX MR 100i NEO impresses during operatio...

Road Machinery

04/11/2024

Wirtgen: Widening of the Ruta 5 highway from Montevideo to the Brazilian Border

Efficient concrete paving solutions from Wirtgen ensure the...

Road Machinery

31/10/2024

Wirtgen: Concrete paving with inset slipform pavers

Wirtgen has been offering machines for inset slipform paving...

Earthmoving Machinery

28/10/2024

Kleemann: Andesite processing in Indonesia

A MOBICAT MC 120 PRO and a MOBISCREEN MSS 802 EVO are deploy...

Earthmoving Machinery

24/10/2024

Benninghoven's REVOC system proven in practice

The REVOC Retrofit solution has been installed at an existin...

Road Machinery

01/10/2024

The Wirtgen Group at Paving Expo 2024

The Wirtgen Group presents groundbreaking technologies at Pa...

Altri International

International

21/11/2024

Kleemann: New compact crusher used for recycling

Impact crusher MOBIREX MR 100i NEO impresses during operatio...

International

21/11/2024

SITECH partners with Royal Engineers to create poppy and demonstrate tech offering

The demostration involved creating a ground-level poppy desi...

International

20/11/2024

Strong and stable RA30 trucks carry the weight at New Caledonian mine

Three Rokbak RA30 trucks are delivering exceptional durabili...

International

20/11/2024

Tadano AC 7.450-1 Performs Double Duty in Wisconsin

A cost-saving and versatile solution was already on site - a...

International

19/11/2024

Liebherr Tower Cranes and John Paul Construction celebrate 50 years of partnership

Irish construction company John Paul Construction is celebra...

International

18/11/2024

The CMC i23 aerial platform: an example of high performances

CMC i23 is designed to maximise operational efficiency in al...