Home \ International \ Volvo: Top 3 tips for profitable operations

Volvo: Top 3 tips for profitable operations

05/12/2018

Pubblicato da Redazione

Low cost per tonne is one of customers’ biggest priorities today. The high-quality design of Volvo’s reliable and fuel-efficient machines goes a long way to fulfilling this requirement – but the percentage of time they are actually used and ho

Low cost per tonne is one of customers’ biggest priorities today. The high-quality design of Volvo’s reliable and fuel-efficient machines goes a long way to fulfilling this requirement – but the percentage of time they are actually used and how they are operated also have a major impact. Here are three actions customers can take today to save even more money.

Delve into the data

It’s standard practice for customers to collect telematics data about their fleet but how many customers are using this information to increase the profitability of their operations? To help make sense of the numbers and set tangible actions for improvement, Volvo CE offers new insight reports, health reports and summary reports. These reports allow customers to see at a glance the benefit they are getting from their fleet and take control of their costs.

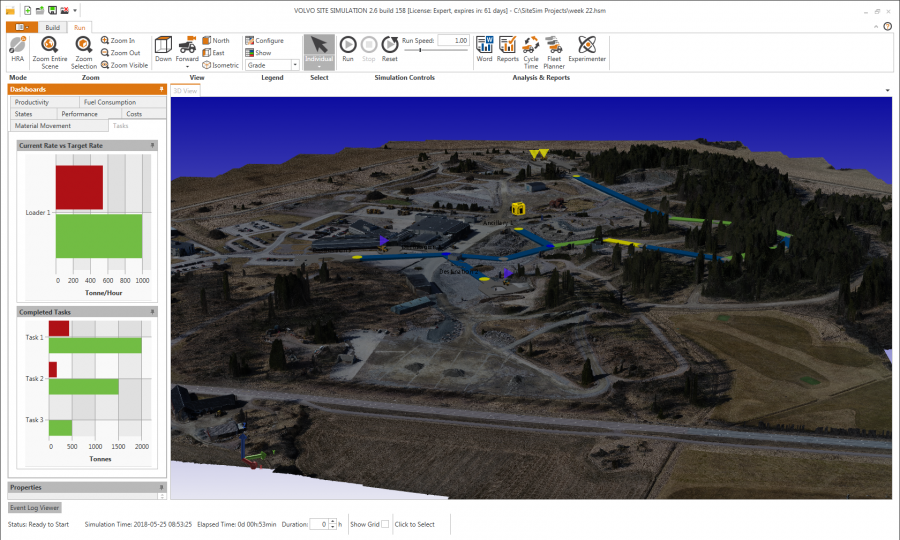

Run a site simulation

Machines with a high idling or waiting time are an unnecessary drain on costs so getting the right set-up onsite is crucial to profitability. Thanks to the latest software and 3D drone photography, Volvo CE can accurately simulate operations on a customer’s entire site for the lowest possible cost per tonne. By inputting the type of material, distance from the loading to dumping points, and topography of the site, a Volvo application engineer can recommend the ideal number and capacity of machines, as well as the optimum routes operators should drive, based on production targets. A few tweaks to the set-up of the site and machine fleet can make an enormous difference to a customer’s bottom line.

Invest in operator training

Operators have an enormous impact on profitability. Inexperienced operators who push the throttle to the bottom all the time, jerk the machine about, and under or overload it with material can send fuel and maintenance costs spinning out of control. That’s before you even consider their level of productivity. Volvo CE and its dealers offer a variety of training courses and programmes both in the field and on realistic simulators to help operators understand how to plan their work, manoeuvre the machine, and make use of all the handy Volvo features to boost their efficiency, accuracy and productivity. It doesn’t take long at all for the investment to pay for itself and machine owners to start reaping the rewards.

Ultime notizie di Volvo CE Italia

Earthmoving Machinery

19/09/2024

Volvo CE inaugurates new facilities to support production of electric wheel loaders in Arvika

The industry shift has taken another exciting leap forward a...

Components

26/06/2024

Operator connectivity with Volvo CE'"My Equipment" digital tool

"My equipment" is a new digital solution from Volvo Construc...

Earthmoving Machinery

17/06/2024

New Volvo excavators elevate customer productivity

A new range of excavators from Volvo Construction Equipment...

Equipments

10/06/2024

Innovative mobile charging solution from Volvo CE set to transform off-grid work

Volvo Construction Equipment (Volvo CE) is launching a new s...

Earthmoving Machinery

29/05/2024

Volvo CE: the catalogue of Product Carbon Footprint

Volvo CE empowers customers with industry’s most extensive c...

Earthmoving Machinery

17/05/2024

Volvo CE has taken a 22% ownership stake in VizaLogix

Volvo CE has taken a 22% ownership stake in VizaLogix, a US-...

Altri International

International

25/11/2024

New Grove GMK3060L-1 drives busy schedule for Mann Crane Hire

• Mann Crane Hire selected the GMK3060L-1 for its class-lead...

International

25/11/2024

Prinoth Unveils Expanded Production Facility in Granby, Canada

Prinoth held an event to announce the official opening of it...

International

23/11/2024

GPMat International takes delivery of two Raimondi T147s residential development in the South of France

- Official agent of France expands its product lineup with t...

International

22/11/2024

Sarens acquires additional SCHEUERLE SPMT K24 modules

renowned for its expertise in crane rental services, heavy l...

International

22/11/2024

Five WOLFF cranes modernize Oslo’s Ulven district

With a total of five WOLFF cranes of type 7534.16 Clear, Wol...

International

21/11/2024

Kleemann: New compact crusher used for recycling

Impact crusher MOBIREX MR 100i NEO impresses during operatio...