Home \ International \ Wirtgen: Key technology – offset concrete paving

Wirtgen: Key technology – offset concrete paving

19/08/2024

Pubblicato da Ettore Zanatta

AutoPilot 2.0 stringless machine control assures precise and cost efficient paving results.

Slipform pavers can be used for paving monolithic concrete constructions with the offset method. Kerbs, gutter profiles, concrete safety barriers, cycle paths, and many other profiles can be paved in one piece with wet concrete. Each individual project requires the right slipform mould and process parameters precisely matched to the specific application. Wirtgen slipform pavers offer the paving crew the extreme flexibility and adaptability they need to achieve optimal results in a broad spectrum of applications. Here, AutoPilot 2.0 makes the paving process even more precise and cost-efficient.

In offset paving applications, the wet concrete is transferred from the concrete mixer to the slipform mould by means of a feeding unit. The concrete in the slipform mould is compacted and moulded as the paver travels forward. The monolithic profile is produced with the desired shape and form at the outlet of the slipform mould. Various parameters can be set to meet the specific requirements of the application and the profile to be paved. With four models, paving widths of up to 4,000 mm, paving heights of up to 3,000 mm, and numerous customisation options, Wirtgen offers machines for every paving scenario.

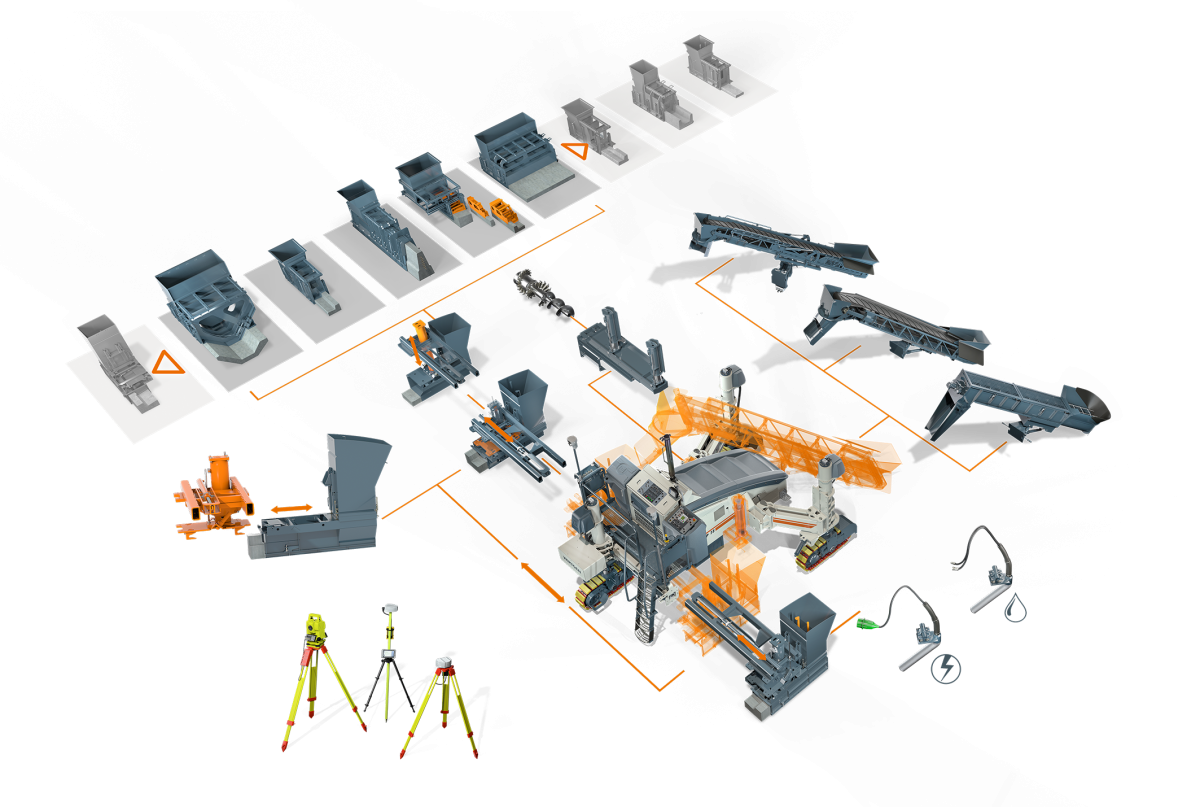

The modular concept of the slipform pavers offers numerous combination options. The unique flexibility of the machine is confirmed not only when configuring it for the first time, but also when reconfiguring it for different applications. The spectrum of possible applications guarantees high machine utilisation rates and maximum cost-efficiency.

A choice of belt and auger conveyors is available for feeding concrete from mixers to the slipform mould. Belt conveyors can transfer large quantities of concrete mix in a short time and are particularly maintenance-friendly. Belt conveyors of different lengths, and also folding belt conveyors, provide additional flexibility on the construction site and during transportation of the machines. Auger conveyors thoroughly remix the concrete on its way to the mould, preventing segregation of the material. The height, pitch, and lateral positioning of the concrete feeding system can be manually adjusted in-place or from the operator’s platform. This means that it can be quickly and easily adapted to the actual situation on the construction site.

The key component of the paver is the slipform mould. It is mounted on the machine with a height-adjustable and laterally-telescoping suspension system that enables it to be easily brought into the right position. The mould can be mounted on either the left or right side of all Wirtgen offset slipform pavers. This ensures that paving can always be carried out in the direction of flowing traffic. With just a few simple steps, the mould can be relocated from one side of the machine to the other on the construction site within a few minutes.

Wirtgen offers various different vibration systems for compacting the concrete. Hydraulic or electric vibrators can be used, depending on the application and requirements. A combination of both types can also be used on the same machine.

The positioning of the track units is also extremely flexible. The various models offer a range of different options for setting up the machine on the construction site. Swing legs on the front track units, also known as parallelogram arms, enable alteration of the track unit spacing and lateral shifting of the centre line. Depending on the model, the pavers also feature laterally telescoping rear track units. This guarantees consistently high machine stability, both on construction sites with limited space and when paving with large offsets between the slipform mould and the machine.

The Wirtgen AutoPilot system provides extremely precise control of slipform pavers without a physical stringline. The system consists of a base station, a tablet computer, and an integrated control unit on the paver. As the system completely eliminates the need for setting up and removing the stringline conventionally used for machine control, it also reduces the associated project times and costs. Instead of this, the machine is guided along a virtual stringline by satellite-aided navigation. This makes the entire paving workflow faster, more efficient, and, in turn, more cost-efficient. At the same time, it also makes the paving of complex geometries such as tight radii or S-bends, significantly easier.

Ultime notizie di Wirtgen Macchine

Earthmoving Machinery

21/11/2024

Kleemann: New compact crusher used for recycling

Impact crusher MOBIREX MR 100i NEO impresses during operatio...

Road Machinery

04/11/2024

Wirtgen: Widening of the Ruta 5 highway from Montevideo to the Brazilian Border

Efficient concrete paving solutions from Wirtgen ensure the...

Road Machinery

31/10/2024

Wirtgen: Concrete paving with inset slipform pavers

Wirtgen has been offering machines for inset slipform paving...

Earthmoving Machinery

28/10/2024

Kleemann: Andesite processing in Indonesia

A MOBICAT MC 120 PRO and a MOBISCREEN MSS 802 EVO are deploy...

Earthmoving Machinery

24/10/2024

Benninghoven's REVOC system proven in practice

The REVOC Retrofit solution has been installed at an existin...

Road Machinery

01/10/2024

The Wirtgen Group at Paving Expo 2024

The Wirtgen Group presents groundbreaking technologies at Pa...

Altri International

International

21/11/2024

Kleemann: New compact crusher used for recycling

Impact crusher MOBIREX MR 100i NEO impresses during operatio...

International

21/11/2024

SITECH partners with Royal Engineers to create poppy and demonstrate tech offering

The demostration involved creating a ground-level poppy desi...

International

20/11/2024

Strong and stable RA30 trucks carry the weight at New Caledonian mine

Three Rokbak RA30 trucks are delivering exceptional durabili...

International

20/11/2024

Tadano AC 7.450-1 Performs Double Duty in Wisconsin

A cost-saving and versatile solution was already on site - a...

International

19/11/2024

Liebherr Tower Cranes and John Paul Construction celebrate 50 years of partnership

Irish construction company John Paul Construction is celebra...

International

18/11/2024

The CMC i23 aerial platform: an example of high performances

CMC i23 is designed to maximise operational efficiency in al...